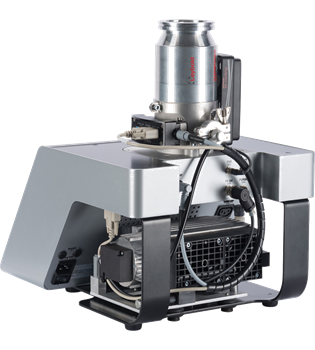

Product Description

Internal Structure

Technical Specifications

Component Details

High-efficiency Permanent Magnet Motor

Insulation grade F, protective grade IP55, soft start operation, stable flow rate. The constant torque range and weak magnetic range are wider, The efficiency of the permanent magnet motor is higher by 20-30% than that of the regular motor.

Integrated Frequency Converter

Adopt the top frequency system in China, with a wide range of speed regulation, and high precision. Quality stability, to ensure that the pressure transmitter signal is transmitted.

Smart Touch Controller

Superior built-in intelligence requires minimal manual operation. A high-precision color electronic screen, clear graphics display, and indication of maintenance information, fault alarms, and safety shutdown alarms.

Special Type Intake Valve

Automatic control of the opening, to ensure the engine fuel injection and lubricating oil circulation.

Ultra-low oil circuit loss, overall efficiency improvement.

Normally open solenoid valve control, emergency stop automatically closed, prevent oil injection.

Cooling System

Large heat exchange area design effectively prevents high-temperature machines and reduces oil emulsification and coking caused by high-temperature.

Excellent Air Filter

An air filter with excellent air purification capability ensures a clean air system and three-stage filtration to maximize air purification and meet standard emissions. It can remove a lot of steam and a small amount of dust gas occasions, the ultimate vacuum is up to 1 Pa.

Reliable Oil and Air Separator

Vertical tangential cyclone separation structure, complete separation of oil and air, easy replacement of cartridge, and reduced maintenance cost.

High-Quality Soundproof Cotton

Compact noise reduction housing, achieving no vibration amplitude during operation, cooperates with high-quality soundproof cotton to further improve noise reduction levels.

Iron Oil Pipe & Air Pipe System

Iron is resistant to high temperature, low temperature, and high pressure, suitable for bad working conditions, completely leak-free, and maintenance-free.

Sanzhi Screw Vacuum Pump VS Water Ring Pump

Features of Vacuum Pump

Multiple filtration

Three-stage filtration minimizes air impurities.

Energy saving

Saves 50-60% of electricity compared to traditional vacuum pumps.

Constant pressure

Constant speed pumping, solving the problem of unstable vacuum pumping.

Higher vacuum degree

The vacuum degree of the vacuum pump on the market is -0.07Mpa, our vacuum degree is -0.098Mpa.

Easy use

Simple structure, easy to install, operate, and maintain.

Packaging&Shipping

Our Advantages

1. Price advantage

Direct to provide customers with ex-factory prices, so that customers are more competitive.

2. Direct deal

All products are supplied directly from the factory and we will offer more cost-effective products.

3. OEM & ODM services

The strong production and management capacity of the factory can provide OEM/ODM service for you.

4. Customised service

We accept non-standard orders, export orders, voltage/power/pressure, etc, which can be customized. If you have demands, please contact us.

5. Accept small order

You can place a small trial order first to test the quality of our products.

6. Fast delivery

High-quality products with timely delivery.

7. Complete authorisation

For distributors, we can provide the full authorization certificate to allow you to sell our SANZHI brand products.

ABOUT US

Sanzhi (ZheJiang ) Compressor Co., Ltd is a specialist in the production of screw air compressors and screw vacuum pumps. The extensive product range includes normal pressure/low-pressure screw air compressors, permanent magnet frequency conversion screw air compressors, two-stage compression screw air compressors, screw air compressors for laser cutting, single-tank mobile screw air compressors, double-tank mobile screw air compressor, electric mobile screw air compressor, diesel mobile screw air compressor, screw vacuum pump, etc.

Our factory is located in HangZhou City, ZheJiang Province, China. We can pick you up from HangZhou International Airport to our factory, 30 kilometers in about 1 hour. Welcome to our company!

Application industry

The items are widely used in wood processing, ceramic processing, printing processing, plastic processing, food packaging, semiconductor materials, pharmaceutical industry, PET blowing industry, petrochemical industry, rubber industry, iron and steel industry, mining industry, spraying industry, tobacco industry, foam factories, brick factories, electronic factories, marine exploration, hydroelectric power stations, ships, military industries and so on.

Successful cases

FAQ

Q1. Are you a trading company or manufacturer?

A: We are a professional manufacturer of screw vacuum pumps, with more than 10 years of experience.

Q2. How do you control quality?

A: 1. The raw materials are strictly inspected.

2. Installation procedures are strictly controlled.

3. Each machine must pass at least 5 hours of continuous testing before leaving the factory.

Q3. What information must I provide to get a suitable machine?

1. How much air delivery capacity (Unit: CFM or m³/Min)

2. How much working pressure (Unit: PSI, Bar or Mpa)

3. What is the voltage and frequency of my country of residence (V/Hz)

4. Whether I need other accessories such as an air tank, filters, and/or air dryers.

Tell us the answer, we will offer a scheme for you!

Q4. What is the general unit conversion?

1Bar = 0.1Mpa = 14.5PSI

1m³/min = 35.32cfm

1KW = 1.34HP

Q5. What is the available voltage vacuum pump?

A: Sanzhi available voltage include 380v/50hz/3p, 400v/50hz/3p, 415v/50hz/3p, 220v/60hz/3p, 440v/60hz/3p, and can be customized according to your requirements.

Q6. How long is the delivery time?

A: For standard voltage,15 working days after the confirmed order. Non-standard, please contact our sales.

Q7. What’s the payment term?

A: TT with 30% deposit in advance, rest balance B/L copy will be ok. USD and RMB can be accepted.

Q8. How about your warranty?

A: One year for the whole machine and 2 years for screw vacuum pump, except for consumable spare parts.

Q9. What about the maintenance?

A: First maintenance needs to be done after 500 hours, and then every 2000-3000 hours to do the normal maintenance, and consider the actual environment.

Q10. Can machines be run in high-temperature environment?

A: Yes, machines would run in high-temperature environment countries. Working temperature from -20° to 45°(-4ºF-113ºF).

Q11. Do you offer OEM service?

A: Yes, with a professional design team, both OEM & ODM orders are highly welcome.

Q12. How long could your vacuum pump be used?

A: Generally, more than 10 years.

Q13. Will you provide some spare parts for the machines?

A: Yes, of course.

Q14. How about your after-sales service?

A: Provide customers with installation and commissioning online instructions, and arrange our engineers to help you with training and installation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technology Support |

|---|---|

| Warranty: | 1 Year, 2 Year |

| Oil or Not: | Oil |

| Structure: | Screw Vacuum Pump |

| Exhauster Method: | Positive Displacement Pump |

| Vacuum Degree: | High Vacuum |

| Samples: |

US$ 10000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Do You Maintain and Troubleshoot Vacuum Pumps?

Maintaining and troubleshooting vacuum pumps is essential to ensure their optimal performance and longevity. Here’s a detailed explanation:

Maintenance of Vacuum Pumps:

1. Regular Inspection: Perform regular visual inspections of the pump to check for any signs of damage, leaks, or abnormal wear. Inspect the motor, belts, couplings, and other components for proper alignment and condition.

2. Lubrication: Follow the manufacturer’s guidelines for lubrication. Some vacuum pumps require regular oil changes or lubrication of moving parts. Ensure that the correct type and amount of lubricant are used.

3. Oil Level Check: Monitor the oil level in oil-sealed pumps and maintain it within the recommended range. Add or replace oil as necessary, following the manufacturer’s instructions.

4. Filter Maintenance: Clean or replace filters regularly to prevent clogging and ensure proper airflow. Clogged filters can impair pump performance and increase energy consumption.

5. Cooling System: If the vacuum pump has a cooling system, inspect it regularly for cleanliness and proper functioning. Clean or replace cooling components as needed to prevent overheating.

6. Seals and Gaskets: Check the seals and gaskets for signs of wear or leakage. Replace any damaged or worn seals promptly to maintain airtightness.

7. Valve Maintenance: If the vacuum pump includes valves, inspect and clean them regularly to ensure proper operation and prevent blockages.

8. Vibration and Noise: Monitor the pump for excessive vibration or unusual noise, which may indicate misalignment, worn bearings, or other mechanical issues. Address these issues promptly to prevent further damage.

Troubleshooting Vacuum Pump Problems:

1. Insufficient Vacuum Level: If the pump is not achieving the desired vacuum level, check for leaks in the system, improper sealing, or worn-out seals. Inspect valves, connections, and seals for leaks and repair or replace as needed.

2. Poor Performance: If the pump is not providing adequate performance, check for clogged filters, insufficient lubrication, or worn-out components. Clean or replace filters, ensure proper lubrication, and replace worn parts as necessary.

3. Overheating: If the pump is overheating, check the cooling system for blockages or insufficient airflow. Clean or replace cooling components and ensure proper ventilation around the pump.

4. Excessive Noise or Vibration: Excessive noise or vibration may indicate misalignment, worn bearings, or other mechanical issues. Inspect and repair or replace damaged or worn parts. Ensure proper alignment and balance of rotating components.

5. Motor Issues: If the pump motor fails to start or operates erratically, check the power supply, electrical connections, and motor components. Test the motor using appropriate electrical testing equipment and consult an electrician or motor specialist if necessary.

6. Excessive Oil Consumption: If the pump is consuming oil at a high rate, check for leaks or other issues that may be causing oil loss. Inspect seals, gaskets, and connections for leaks and repair as needed.

7. Abnormal Odors: Unusual odors, such as a burning smell, may indicate overheating or other mechanical problems. Address the issue promptly and consult a technician if necessary.

8. Manufacturer Guidelines: Always refer to the manufacturer’s guidelines and recommendations for maintenance and troubleshooting specific to your vacuum pump model. Follow the prescribed maintenance schedule and seek professional assistance when needed.

By following proper maintenance procedures and promptly addressing any troubleshooting issues, you can ensure the reliable operation and longevity of your vacuum pump.

How Do Vacuum Pumps Affect the Performance of Vacuum Chambers?

When it comes to the performance of vacuum chambers, vacuum pumps play a critical role. Here’s a detailed explanation:

Vacuum chambers are enclosed spaces designed to create and maintain a low-pressure environment. They are used in various industries and scientific applications, such as manufacturing, research, and material processing. Vacuum pumps are used to evacuate air and other gases from the chamber, creating a vacuum or low-pressure condition. The performance of vacuum chambers is directly influenced by the characteristics and operation of the vacuum pumps used.

Here are some key ways in which vacuum pumps affect the performance of vacuum chambers:

1. Achieving and Maintaining Vacuum Levels: The primary function of vacuum pumps is to create and maintain the desired vacuum level within the chamber. Vacuum pumps remove air and other gases, reducing the pressure inside the chamber. The efficiency and capacity of the vacuum pump determine how quickly the desired vacuum level is achieved and how well it is maintained. High-performance vacuum pumps can rapidly evacuate the chamber and maintain the desired vacuum level even when there are gas leaks or continuous gas production within the chamber.

2. Pumping Speed: The pumping speed of a vacuum pump refers to the volume of gas it can remove from the chamber per unit of time. The pumping speed affects the rate at which the chamber can be evacuated and the time required to achieve the desired vacuum level. A higher pumping speed allows for faster evacuation and shorter cycle times, improving the overall efficiency of the vacuum chamber.

3. Ultimate Vacuum Level: The ultimate vacuum level is the lowest pressure that can be achieved in the chamber. It depends on the design and performance of the vacuum pump. Higher-quality vacuum pumps can achieve lower ultimate vacuum levels, which are important for applications requiring higher levels of vacuum or for processes that are sensitive to residual gases.

4. Leak Detection and Gas Removal: Vacuum pumps can also assist in leak detection and gas removal within the chamber. By continuously evacuating the chamber, any leaks or gas ingress can be identified and addressed promptly. This ensures that the chamber maintains the desired vacuum level and minimizes the presence of contaminants or unwanted gases.

5. Contamination Control: Some vacuum pumps, such as oil-sealed pumps, use lubricating fluids that can introduce contaminants into the chamber. These contaminants may be undesirable for certain applications, such as semiconductor manufacturing or research. Therefore, the choice of vacuum pump and its potential for introducing contaminants should be considered to maintain the required cleanliness and purity of the vacuum chamber.

6. Noise and Vibrations: Vacuum pumps can generate noise and vibrations during operation, which can impact the performance and usability of the vacuum chamber. Excessive noise or vibrations can interfere with delicate experiments, affect the accuracy of measurements, or cause mechanical stress on the chamber components. Selecting vacuum pumps with low noise and vibration levels is important for maintaining optimal chamber performance.

It’s important to note that the specific requirements and performance factors of a vacuum chamber can vary depending on the application. Different types of vacuum pumps, such as rotary vane pumps, dry pumps, or turbomolecular pumps, offer varying capabilities and features that cater to specific needs. The choice of vacuum pump should consider factors such as the desired vacuum level, pumping speed, ultimate vacuum, contamination control, noise and vibration levels, and compatibility with the chamber materials and gases used.

In summary, vacuum pumps have a significant impact on the performance of vacuum chambers. They enable the creation and maintenance of the desired vacuum level, affect the pumping speed and ultimate vacuum achieved, assist in leak detection and gas removal, and influence contamination control. Careful consideration of the vacuum pump selection ensures optimal chamber performance for various applications.

How Are Vacuum Pumps Different from Air Compressors?

Vacuum pumps and air compressors are both mechanical devices used to manipulate air and gas, but they serve opposite purposes. Here’s a detailed explanation of their differences:

1. Function:

– Vacuum Pumps: Vacuum pumps are designed to remove or reduce the pressure within a closed system, creating a vacuum or low-pressure environment. They extract air or gas from a chamber, creating suction or negative pressure.

– Air Compressors: Air compressors, on the other hand, are used to increase the pressure of air or gas. They take in ambient air or gas and compress it, resulting in higher pressure and a compacted volume of air or gas.

2. Pressure Range:

– Vacuum Pumps: Vacuum pumps are capable of generating pressures below atmospheric pressure or absolute zero pressure. The pressure range typically extends into the negative range, expressed in units such as torr or pascal.

– Air Compressors: Air compressors, on the contrary, operate in the positive pressure range. They increase the pressure above atmospheric pressure, typically measured in units like pounds per square inch (psi) or bar.

3. Applications:

– Vacuum Pumps: Vacuum pumps have various applications where the creation of a vacuum or low-pressure environment is required. They are used in processes such as vacuum distillation, vacuum drying, vacuum packaging, and vacuum filtration. They are also essential in scientific research, semiconductor manufacturing, medical suction devices, and many other industries.

– Air Compressors: Air compressors find applications where compressed air or gas at high pressure is needed. They are used in pneumatic tools, manufacturing processes, air conditioning systems, power generation, and inflating tires. Compressed air is versatile and can be employed in numerous industrial and commercial applications.

4. Design and Mechanism:

– Vacuum Pumps: Vacuum pumps are designed to create a vacuum by removing air or gas from a closed system. They may use mechanisms such as positive displacement, entrapment, or momentum transfer to achieve the desired vacuum level. Examples of vacuum pump types include rotary vane pumps, diaphragm pumps, and diffusion pumps.

– Air Compressors: Air compressors are engineered to compress air or gas, increasing its pressure and decreasing its volume. They use mechanisms like reciprocating pistons, rotary screws, or centrifugal force to compress the air or gas. Common types of air compressors include reciprocating compressors, rotary screw compressors, and centrifugal compressors.

5. Direction of Air/Gas Flow:

– Vacuum Pumps: Vacuum pumps draw air or gas into the pump and then expel it from the system, creating a vacuum within the chamber or system being evacuated.

– Air Compressors: Air compressors take in ambient air or gas and compress it, increasing its pressure and storing it in a tank or delivering it directly to the desired application.

While vacuum pumps and air compressors have different functions and operate under distinct pressure ranges, they are both vital in various industries and applications. Vacuum pumps create and maintain a vacuum or low-pressure environment, while air compressors compress air or gas to higher pressures for different uses and processes.

editor by Dream 2024-04-29

China Best Sales Air Cooled Screw Vacuum Pumps for Vacuum Evaporation supplier

Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used for Vacuum Furnaces?

Yes, vacuum pumps can be used for vacuum furnaces. Here’s a detailed explanation:

Vacuum furnaces are specialized heating systems used in various industries for heat treatment processes that require controlled environments with low or no atmospheric pressure. Vacuum pumps play a crucial role in creating and maintaining the vacuum conditions necessary for the operation of vacuum furnaces.

Here are some key points regarding the use of vacuum pumps in vacuum furnaces:

1. Vacuum Creation: Vacuum pumps are used to evacuate the furnace chamber, creating a low-pressure or near-vacuum environment. This is essential for the heat treatment processes carried out in the furnace, as it helps eliminate oxygen and other reactive gases, preventing oxidation or unwanted chemical reactions with the heated materials.

2. Pressure Control: Vacuum pumps provide the means to control and maintain the desired pressure levels within the furnace chamber during the heat treatment process. Precise pressure control is necessary to achieve the desired metallurgical and material property changes during processes such as annealing, brazing, sintering, and hardening.

3. Contamination Prevention: By removing gases and impurities from the furnace chamber, vacuum pumps help prevent contamination of the heated materials. This is particularly important in applications where cleanliness and purity of the processed materials are critical, such as in the aerospace, automotive, and medical industries.

4. Rapid Cooling: Some vacuum furnace systems incorporate rapid cooling capabilities, known as quenching. Vacuum pumps assist in facilitating the rapid cooling process by removing the heat generated during quenching, ensuring efficient cooling and minimizing distortion or other unwanted effects on the treated materials.

5. Process Flexibility: Vacuum pumps provide flexibility in the type of heat treatment processes that can be performed in vacuum furnaces. Different heat treatment techniques, such as vacuum annealing, vacuum brazing, or vacuum carburizing, require specific pressure levels and atmospheric conditions that can be achieved and maintained with the use of vacuum pumps.

6. Vacuum Pump Types: Different types of vacuum pumps can be used in vacuum furnaces, depending on the specific requirements of the heat treatment process. Commonly used vacuum pump technologies include oil-sealed rotary vane pumps, dry screw pumps, diffusion pumps, and cryogenic pumps. The choice of vacuum pump depends on factors such as required vacuum level, pumping speed, reliability, and compatibility with the process gases.

7. Maintenance and Monitoring: Proper maintenance and monitoring of vacuum pumps are essential to ensure their optimal performance and reliability. Regular inspections, lubrication, and replacement of consumables (such as oil or filters) are necessary to maintain the efficiency and longevity of the vacuum pump system.

8. Safety Considerations: Operating vacuum furnaces with vacuum pumps requires adherence to safety protocols. This includes proper handling of potentially hazardous gases or chemicals used in the heat treatment processes, as well as following safety guidelines for operating and maintaining the vacuum pump system.

Overall, vacuum pumps are integral components of vacuum furnaces, enabling the creation and maintenance of the required vacuum conditions for precise and controlled heat treatment processes. They contribute to the quality, consistency, and efficiency of the heat treatment operations performed in vacuum furnaces across a wide range of industries.

Can Vacuum Pumps Be Used for Soil and Groundwater Remediation?

Vacuum pumps are indeed widely used for soil and groundwater remediation. Here’s a detailed explanation:

Soil and groundwater remediation refers to the process of removing contaminants from the soil and groundwater to restore environmental quality and protect human health. Vacuum pumps play a crucial role in various remediation techniques by facilitating the extraction and treatment of contaminated media. Some of the common applications of vacuum pumps in soil and groundwater remediation include:

1. Soil Vapor Extraction (SVE): Soil vapor extraction is a widely used remediation technique for volatile contaminants present in the subsurface. It involves the extraction of vapors from the soil by applying a vacuum to the subsurface through wells or trenches. Vacuum pumps create a pressure gradient that induces the movement of vapors towards the extraction points. The extracted vapors are then treated to remove or destroy the contaminants. Vacuum pumps play a vital role in SVE by maintaining the necessary negative pressure to enhance the volatilization and extraction of contaminants from the soil.

2. Dual-Phase Extraction (DPE): Dual-phase extraction is a remediation method used for the simultaneous extraction of both liquids (such as groundwater) and vapors (such as volatile organic compounds) from the subsurface. Vacuum pumps are utilized to create a vacuum in extraction wells or points, drawing out both the liquid and vapor phases. The extracted groundwater and vapors are then separated and treated accordingly. Vacuum pumps are essential in DPE systems for efficient and controlled extraction of both liquid and vapor-phase contaminants.

3. Groundwater Pumping and Treatment: Vacuum pumps are also employed in groundwater remediation through the process of pumping and treatment. They are used to extract contaminated groundwater from wells or recovery trenches. By creating a vacuum or negative pressure, vacuum pumps facilitate the flow of groundwater towards the extraction points. The extracted groundwater is then treated to remove or neutralize the contaminants before being discharged or re-injected into the ground. Vacuum pumps play a critical role in maintaining the required flow rates and hydraulic gradients for effective groundwater extraction and treatment.

4. Air Sparging: Air sparging is a remediation technique used to treat groundwater and soil contaminated with volatile organic compounds (VOCs). It involves the injection of air or oxygen into the subsurface to enhance the volatilization of contaminants. Vacuum pumps are utilized in air sparging systems to create a vacuum or negative pressure zone in wells or points surrounding the contaminated area. This induces the movement of air and oxygen through the soil, facilitating the release and volatilization of VOCs. Vacuum pumps are essential in air sparging by maintaining the necessary negative pressure gradient for effective contaminant removal.

5. Vacuum-Enhanced Recovery: Vacuum-enhanced recovery, also known as vacuum-enhanced extraction, is a remediation technique used to recover non-aqueous phase liquids (NAPLs) or dense non-aqueous phase liquids (DNAPLs) from the subsurface. Vacuum pumps are employed to create a vacuum or negative pressure gradient in recovery wells or trenches. This encourages the movement and extraction of NAPLs or DNAPLs towards the recovery points. Vacuum pumps facilitate the efficient recovery of these dense contaminants, which may not be easily recoverable using traditional pumping methods.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, liquid ring pumps, or air-cooled pumps, may be used in soil and groundwater remediation depending on the specific requirements of the remediation technique and the nature of the contaminants.

In summary, vacuum pumps play a vital role in various soil and groundwater remediation techniques, including soil vapor extraction, dual-phase extraction, groundwater pumping and treatment, air sparging, and vacuum-enhanced recovery. By creating and maintaining the necessary pressure differentials, vacuum pumps enable the efficient extraction, treatment, and removal of contaminants, contributing to the restoration of soil and groundwater quality.

How Do You Choose the Right Size Vacuum Pump for a Specific Application?

Choosing the right size vacuum pump for a specific application involves considering several factors to ensure optimal performance and efficiency. Here’s a detailed explanation:

1. Required Vacuum Level: The first consideration is the desired vacuum level for your application. Different applications have varying vacuum level requirements, ranging from low vacuum to high vacuum or even ultra-high vacuum. Determine the specific vacuum level needed, such as microns of mercury (mmHg) or pascals (Pa), and choose a vacuum pump capable of achieving and maintaining that level.

2. Pumping Speed: The pumping speed, also known as the displacement or flow rate, is the volume of gas a vacuum pump can remove from a system per unit of time. It is typically expressed in liters per second (L/s) or cubic feet per minute (CFM). Consider the required pumping speed for your application, which depends on factors such as the volume of the system, the gas load, and the desired evacuation time.

3. Gas Load and Composition: The type and composition of the gas or vapor being pumped play a significant role in selecting the right vacuum pump. Different pumps have varying capabilities and compatibilities with specific gases. Some pumps may be suitable for pumping only non-reactive gases, while others can handle corrosive gases or vapors. Consider the gas load and its potential impact on the pump’s performance and materials of construction.

4. Backing Pump Requirements: In some applications, a vacuum pump may require a backing pump to reach and maintain the desired vacuum level. A backing pump provides a rough vacuum, which is then further processed by the primary vacuum pump. Consider whether your application requires a backing pump and ensure compatibility and proper sizing between the primary pump and the backing pump.

5. System Leakage: Evaluate the potential leakage in your system. If your system has significant leakage, you may need a vacuum pump with a higher pumping speed to compensate for the continuous influx of gas. Additionally, consider the impact of leakage on the required vacuum level and the pump’s ability to maintain it.

6. Power Requirements and Operating Cost: Consider the power requirements of the vacuum pump and ensure that your facility can provide the necessary electrical supply. Additionally, assess the operating cost, including energy consumption and maintenance requirements, to choose a pump that aligns with your budget and operational considerations.

7. Size and Space Constraints: Take into account the physical size of the vacuum pump and whether it can fit within the available space in your facility. Consider factors such as pump dimensions, weight, and the need for any additional accessories or support equipment.

8. Manufacturer’s Recommendations and Expert Advice: Consult the manufacturer’s specifications, guidelines, and recommendations for selecting the right pump for your specific application. Additionally, seek expert advice from vacuum pump specialists or engineers who can provide insights based on their experience and knowledge.

By considering these factors and evaluating the specific requirements of your application, you can select the right size vacuum pump that meets the desired vacuum level, pumping speed, gas compatibility, and other essential criteria. Choosing the appropriate vacuum pump ensures efficient operation, optimal performance, and longevity for your application.

editor by Dream 2024-04-22

China wholesaler Vacuum Pump Rotary Roots Liquid-Ring Water Piston Dry Portable Screw Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Air Vacuum Pump supplier

Product Description

Vacuum pump Roots Liquid-ring water piston Rotary Dry portable Screw scroll Reciprocating diaphragm centrifugal positive displacement AC DC Air vacuum pump

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the five bit machine, sealing double sealing structure + mechanical seal for Teflon maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

Typical Applications

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

Specifications

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

Characteristic Curves

Overall Dimensions

company information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Optional |

|---|---|

| Inlet Diam. (mm): | 100/200mm |

| Motor Power (Kw): | 4/7.5 Kw |

| Ultimate Pressure (PA): | 0.05 |

| Transport Package: | Wooden Case |

| Trademark: | OEM |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Can diaphragm vacuum pumps be integrated into existing laboratory setups and industrial processes?

Yes, diaphragm vacuum pumps can be integrated into existing laboratory setups and industrial processes. Here’s a detailed explanation:

Laboratory Setups: Diaphragm vacuum pumps are commonly used in laboratory environments for various applications, including filtration, aspiration, degassing, desiccation, and vacuum drying. They can be easily integrated into existing laboratory setups due to their compact size, versatility, and compatibility with a wide range of laboratory equipment.

Diaphragm vacuum pumps can connect to laboratory apparatus such as filtration systems, rotary evaporators, vacuum ovens, and vacuum desiccators. They often feature standard connections, such as hose barbs or quick-connect fittings, that allow for easy and secure attachment to different laboratory devices. In many cases, diaphragm vacuum pumps can directly replace other types of vacuum pumps without requiring significant modifications to the existing setup.

The ability to integrate diaphragm vacuum pumps into laboratory setups offers advantages such as:

– Oil-Free Operation: Diaphragm pumps do not require oil lubrication, eliminating the risk of oil contamination in the laboratory setup and reducing maintenance requirements.

– Quiet Operation: Diaphragm pumps are known for their relatively quiet operation, making them suitable for laboratory environments where noise reduction is desirable.

– Chemical Compatibility: Diaphragm pumps are available in models constructed with chemically resistant materials, allowing them to handle a wide range of solvents, gases, and vapors encountered in laboratory processes.

Industrial Processes: Diaphragm vacuum pumps can also be integrated into various industrial processes. They find applications in industries such as pharmaceuticals, food and beverage, electronics, automotive, and materials processing.

In industrial settings, diaphragm vacuum pumps can be used for tasks such as vacuum packaging, degassing, solvent recovery, pneumatic conveying, and vacuum drying. They can be incorporated into existing process lines and equipment, providing the necessary vacuum levels and performance required for the specific application.

Diaphragm vacuum pumps offer advantages in industrial processes, including:

– Reliable Performance: Diaphragm pumps are known for their reliable operation, providing consistent vacuum levels and performance over time.

– Energy Efficiency: Diaphragm pumps can be designed to be energy-efficient, contributing to cost savings and sustainability in industrial operations.

– Low Maintenance: Diaphragm pumps generally have low maintenance requirements compared to other types of vacuum pumps, reducing downtime and operating costs.

When integrating diaphragm vacuum pumps into laboratory or industrial setups, it’s important to consider factors such as the required vacuum level, flow rate, compatibility with existing equipment, and any specific environmental or safety considerations. Additionally, consulting the manufacturer’s guidelines and seeking expert advice can ensure proper integration and optimal performance.

In summary, diaphragm vacuum pumps can be easily integrated into existing laboratory setups and industrial processes. Their compact size, versatility, oil-free operation, chemical compatibility, and reliable performance make them suitable for a wide range of applications. Whether in laboratory or industrial settings, diaphragm vacuum pumps offer advantages such as quiet operation, energy efficiency, and low maintenance requirements.

Are diaphragm vacuum pumps suitable for applications requiring oil-free and contamination-free vacuum?

Yes, diaphragm vacuum pumps are well-suited for applications that require oil-free and contamination-free vacuum conditions. Here’s a detailed explanation:

Diaphragm vacuum pumps are designed to operate without the use of oil lubrication. Instead of oil, these pumps utilize a flexible diaphragm that moves back and forth to create the pumping action. This oil-free operation eliminates the risk of oil contamination in the vacuum system.

By eliminating the need for oil, diaphragm vacuum pumps are particularly advantageous for applications where oil contamination can be detrimental. Here are some examples of applications that benefit from the oil-free operation of diaphragm pumps:

– Laboratory Research: In laboratory settings, diaphragm vacuum pumps are commonly used in analytical instruments such as gas chromatographs and mass spectrometers. These instruments require a clean and oil-free vacuum environment to ensure accurate and reliable results.

– Pharmaceutical and Biotechnology: Diaphragm pumps are extensively used in pharmaceutical and biotechnology industries for processes such as vacuum filtration, solvent recovery, and sample preparation. These applications demand a contamination-free vacuum to maintain the purity and integrity of the products.

– Electronics Manufacturing: In the electronics industry, diaphragm vacuum pumps are employed for various processes, including component handling, pick-and-place operations, and soldering. The oil-free operation of diaphragm pumps prevents oil mist or vapor from contaminating sensitive electronic components.

– Food and Beverage Processing: Diaphragm pumps find applications in the food and beverage industry for processes such as vacuum packaging, degassing, and filtration. The oil-free operation ensures that the vacuum does not introduce any unwanted contaminants into the food or beverage products.

It’s important to note that while diaphragm vacuum pumps offer oil-free and contamination-free vacuum conditions, the overall cleanliness of the vacuum system also depends on other components and accessories used in conjunction with the pump. Proper maintenance, regular cleaning, and appropriate filtration mechanisms should be implemented to maintain a high level of cleanliness in the vacuum system.

In summary, diaphragm vacuum pumps are suitable for applications that require oil-free and contamination-free vacuum conditions. Their oil-free operation makes them ideal for applications where oil contamination can compromise product quality, accuracy, or the performance of sensitive equipment.

What are the key components of a diaphragm vacuum pump?

A diaphragm vacuum pump consists of several key components that work together to create vacuum or low-pressure conditions. Here’s a detailed explanation of these components:

1. Diaphragm:

The diaphragm is the central component of a diaphragm vacuum pump. It is a flexible membrane that moves back and forth within a chamber to generate the pumping action. The diaphragm is typically made of a durable, chemically resistant material such as rubber or elastomer. It is responsible for creating changes in the chamber volume, resulting in suction and compression of gases.

2. Pumping Chamber:

The pumping chamber houses the diaphragm and provides the space for the diaphragm’s movement. It is a sealed chamber that expands and contracts as the diaphragm flexes. The pumping chamber is designed to be gas-tight to prevent leakage and maintain the vacuum or low-pressure conditions.

3. Inlet and Outlet Valves:

Diaphragm vacuum pumps typically have inlet and outlet valves that control the flow of gases into and out of the pumping chamber.

– Inlet Valve: The inlet valve allows gas or vapor to enter the pumping chamber during the suction phase. It opens when the diaphragm moves downward, creating a low-pressure region within the chamber.

– Outlet Valve: The outlet valve allows the compressed gas to be expelled from the pumping chamber during the compression and exhaust phases. It opens when the diaphragm moves upward, compressing the gas and forcing it out of the chamber.

4. Drive Mechanism:

The drive mechanism provides the motion and power to move the diaphragm back and forth within the pumping chamber. It can be an electric motor, a pneumatic actuator, or other mechanisms depending on the pump design. The drive mechanism ensures the continuous operation of the diaphragm, creating the pumping action.

5. Check Valves:

Check valves, also known as one-way valves or non-return valves, are often incorporated into diaphragm vacuum pumps to ensure the flow of gas occurs in the desired direction.

– Inlet Check Valve: The inlet check valve allows gas to enter the pumping chamber during the suction phase but prevents backflow when the diaphragm moves upward during compression and exhaust phases.

– Outlet Check Valve: The outlet check valve allows the compressed gas to be expelled from the pumping chamber during the compression and exhaust phases but prevents backflow into the chamber during the suction phase.

6. Housing and Mounting:

The housing of a diaphragm vacuum pump encloses and protects the internal components. It is typically made of a sturdy material such as metal or plastic. The housing also provides mounting points for the pump, allowing it to be securely installed in various orientations or integrated into larger systems.

7. Control and Monitoring Features:

Some diaphragm vacuum pumps may include control and monitoring features such as power switches, pressure gauges, or digital interfaces. These features allow for convenient operation, monitoring of vacuum levels, and integration with control systems or automation.

It’s important to note that the specific design and configuration of diaphragm vacuum pumps may vary across different manufacturers and models. Consulting the manufacturer’s specifications and documentation will provide detailed information on the components, construction, and performance characteristics of a particular diaphragm pump.

The combination of the diaphragm, pumping chamber, valves, drive mechanism, check valves, housing, and control features enables diaphragm vacuum pumps to generate efficient and reliable vacuum or low-pressure conditions for a wide range of applications.

editor by CX 2024-04-16

China high quality Air Cooled Screw Vacuum Pumps for Cosmetics and Sanitary Products supplier

Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.Dry Oil-Free Air Cooling Screw Vacuum Pump ,This is an advanced and widely used vacuum pump at present, It is 1 of the best-selling products of our company.

It adopts explosion-proof motor with high configuration, It has the characteristics of low noise, no oil and pollution, clean and high vacuum, simple and convenient use, operation and maintenance, Widely used in many industries, For example, oil and gas recovery, vacuum coating, biomedicine, food processing, single crystal furnace, vacuum forming, vacuum melting, electronic photovoltaic, semiconductor synthesis and many other industries are used.

The dry oil-free screw vacuum pump produced by our company is divided into air cooling and water cooling according to the extraction rate, and there are many models for you to choose.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

Air cooling Dry screw vacuum pump

| Type (Air cooled series) |

Basic parameters | ||||||||

| Pumping speed (m3/h) |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber (mm) |

outlet caliber (mm) | Pump head weight (kg) |

noise dB(A) | Overall dimension (length*width*height) (mm) |

|

| LG-10 | 10 | ≤5 | 0.75 | 2730 | KF16 | KF16 | 30 | ≤ 72 | 655x260x285 |

| LG-20 | 20 | ≤5 | 1.1 | 2840 | KF25 | KF25 | 55 | ≤72 | 720x305x370 |

| LG-50 | 50 | ≤10 | 2.2 | 2850 | KF40 | KF40 | 90 | ≤75 | 920x350x420 |

| LG-70 | 70 | ≤30 | 3 | 2850 | KF40 | KF40 | 110 | ≤75 | 910x390x460 |

| LG-90 | 90 | ≤30 | 4 | 2870 | KF50 | KF50 | 125 | ≤80 | 1000x410x495 |

Water cooling Dry screw vacuum pump

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Air cooling Dry screw vacuum pump

Water cooling Dry screw vacuum pump

Detailed Photos

Vacuum pumps are used in oiling machines

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

New plant plHangZhou

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

High precision machining equipment

The company cooperates with many scientific research institutions and universities, such as ZheJiang University, China University of petroleum, ZheJiang Institute of mechanical design, etc.with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents.Our technology is leading, the product quality is stable, the product has a good reputation in China’s domestic market, is sold all over the country, and is exported to Europe, America, Africa, the Middle East and Southeast Asia,We adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

Product quality wins consumer cooperation

In shipment

ISO 9001 High tech enterprise certificate

Welcome to send your needs, we will provide you with the best service,

provide the greatest help!!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

Basic knowledge of vacuum pump

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its main job is to create a relative vacuum within a given volume or volumes. There are many types of vacuum pumps. This article will describe how they work, their types, and their applications.

How it works

A vacuum pump is a mechanical device that removes gas from a system by applying it to a higher pressure than the surrounding atmosphere. The working principle of the vacuum pump is based on the principle of gas transfer and entrapment. Vacuum pumps can be classified according to their vacuum level and the number of molecules that can be removed per cubic centimeter of space. In medium to high vacuum, viscous flow occurs when gas molecules collide with each other. Increasing the vacuum causes molecular or transitional flow.

A vacuum pump has several components that make it a versatile tool. One of the main components is the motor, which consists of a rotor and a stator. The rotor and stator contain coils that generate a magnetic field when excited. Both parts must be mounted on a base that supports the weight of the pump. There is also an oil drain that circulates oil throughout the system for lubrication and cooling purposes.

Another type of vacuum pump is the liquid ring vacuum pump. It works by positioning the impeller above or below the blades. Liquid ring pumps can also adjust the speed of the impeller. However, if you plan to use this type of pump, it is advisable to consult a specialist.

Vacuum pumps work by moving gas molecules to areas of higher or lower pressure. As the pressure decreases, the removal of the molecules becomes more difficult. Industrial vacuum systems require pumps capable of operating in the 1 to 10-6 Torr range.

Type

There are different types of vacuum pumps. They are used in many different applications, such as laboratories. The main purpose of these pumps is to remove air or gas molecules from the vacuum chamber. Different types of pumps use different techniques to achieve this. Some types of pumps use positive displacement, while others use liquid ring, molecular transfer, and entrapment techniques.

Some of these pumps are used in industrial processes, including making vacuum tubes, CRTs, electric lights, and semiconductor processing. They are also used in motor vehicles to power hydraulic components and aircraft. The gyroscope is usually controlled by these pumps. In some cases, they are also used in medical settings.

How a vacuum pump works depends on the type of gas being pumped. There are three main types: positive displacement, negative displacement, and momentum transfer. Depending on the type of lubrication, these principles can be further divided into different types of pumps. For example, dry vacuum pumps are less sensitive to gases and vapors.

Another type of vacuum pump is called a rotary vane pump. This type of pump has two main components, the rotor and the vacuum chamber. These pumps work by rotating moving parts against the pump casing. The mating surfaces of rotary pumps are designed with very small clearances to prevent fluid leakage to the low pressure side. They are suitable for vacuum applications requiring low pulsation and high continuous flow. However, they are not suitable for use with grinding media.

There are many types of vacuum pumps and it is important to choose the right one for your application. The type of pump depends on the needs and purpose of the system. The larger ones can work continuously, and the smaller ones are more suitable for intermittent use.

Apply

Vacuum pumps are used in a variety of industrial and scientific processes. For example, they are used in the production of vacuum tubes, CRTs, and electric lamps. They are also used in semiconductor processing. Vacuum pumps are also used as mechanical supports for other equipment. For example, there may be multiple vacuum pumps on the engine of a motor vehicle that powers the hydraulic components of an aircraft. In addition, they are often used in fusion research.

The most common type of vacuum pump used in the laboratory is the rotary vane pump. It works by directing airflow through a series of rotating blades in a circular housing. As the blades pass through the casing, they remove gas from the cavity and create a vacuum. Rotary pumps are usually single or double-stage and can handle pressures between 10 and 6 bar. It also has a high pumping speed.

Vacuum pumps are also used to fabricate solar cells on wafers. This involves a range of processes including doping, diffusion, dry etching, plasma-enhanced chemical vapor deposition, and bulk powder generation. These applications depend on the type of vacuum pump used in the process, and the vacuum pump chosen should be designed for the environment.

While there are several types of vacuum pumps available, their basic working principles remain the same. Each has different functions and capacities, depending on the type of vacuum. Generally divided into positive displacement pump, rotary vane pump, liquid ring pump, and molecular delivery pump.

Maintenance

The party responsible for general maintenance and repairs is the Principal Investigator (PI). Agknxs must be followed and approved by the PI and other relevant laboratory personnel. The Agknx provides guidelines for routine maintenance of vacuum pump equipment. Agknxs are not intended to replace detailed routine inspections of vacuum pump equipment, which should be performed by certified/qualified service personnel. If the device fails, the user should contact PI or RP for assistance.

First, check the vacuum pump for any loose parts. Make sure the inlet and outlet pressure gauges are open. When the proper pressure is shown, open the gate valve. Also, check the vacuum pump head and flow. Flow and head should be within the range indicated on the label. Bearing temperature should be within 35°F and maximum temperature should not exceed 80°F. The vacuum pump bushing should be replaced when it is severely worn.

If the vacuum pump has experienced several abnormal operating conditions, a performance test should be performed. Results should be compared to reference values to identify abnormalities. To avoid premature pump failure, a systematic approach to predictive maintenance is essential. This is a relatively new area in the semiconductor industry, but leading semiconductor companies and major vacuum pump suppliers have yet to develop a consistent approach.

A simplified pump-down test method is proposed to evaluate the performance of vacuum pumps. The method includes simulated aeration field tests and four pump performance indicators. Performance metrics are evaluated under gas-loaded, idle, and gas-load-dependent test conditions.

Cost

The total cost of a vacuum pump consists of two main components: the initial investment and ongoing maintenance costs. The latter is the most expensive component, as it consumes about four to five times the initial investment. Therefore, choosing a more energy-efficient model is a good way to reduce the total system cost and payback period.

The initial cost of a vacuum pump is about $786. Oil-lubricated rotary vane pumps are the cheapest, while oil-free rotary vane pumps are slightly more expensive. Non-contact pumps also cost slightly more. The cost of a vacuum pump is not high, but it is a factor that needs careful consideration.

When choosing a vacuum pump, it is important to consider the type of gas being pumped. Some pumps are only suitable for pumping air, while others are designed to pump helium. Oil-free air has a different pumping rate profile than air. Therefore, you need to consider the characteristics of the medium to ensure that the pump meets your requirements. The cost of a vacuum pump can be much higher than the purchase price, as the daily running and maintenance costs can be much higher.

Lubricated vacuum pumps tend to be more durable and less expensive, but they may require more maintenance. Maintenance costs will depend on the type of gas that needs to be pumped. Lighter gases need to be pumped slowly, while heavier gases need to be pumped faster. The maintenance level of a vacuum pump also depends on how often it needs to be lubricated.

Diaphragm vacuum pumps require regular maintenance and oil changes. The oil in the diaphragm pump should be changed every 3000 hours of use. The pump is also resistant to chemicals and corrosion. Therefore, it can be used in acidic and viscous products.

editor by CX 2024-03-26

China supplier Air Cooled Screw Vacuum Pumps for Mineral Flotation Agent, Casting Chemicals with high quality

Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

What Are the Advantages of Using Oil-Sealed Vacuum Pumps?

Oil-sealed vacuum pumps offer several advantages in various applications. Here’s a detailed explanation:

1. High Vacuum Performance: Oil-sealed vacuum pumps are known for their ability to achieve high levels of vacuum. They can create and maintain deep vacuum levels, making them suitable for applications that require a low-pressure environment. The use of oil as a sealing and lubricating medium helps in achieving efficient vacuum performance.

2. Wide Operating Range: Oil-sealed vacuum pumps have a wide operating range, allowing them to handle a broad spectrum of vacuum levels. They can operate effectively in both low-pressure and high-vacuum conditions, making them versatile for different applications across various industries.

3. Efficient and Reliable Operation: These pumps are known for their reliability and consistent performance. The oil-sealed design provides effective sealing, preventing air leakage and maintaining a stable vacuum level. They are designed to operate continuously for extended periods without significant performance degradation, making them suitable for continuous industrial processes.

4. Contamination Handling: Oil-sealed vacuum pumps are effective in handling certain types of contaminants that may be present in the process gases or air being evacuated. The oil acts as a barrier, trapping and absorbing certain particulates, moisture, and chemical vapors, preventing them from reaching the pump mechanism. This helps protect the pump internals from potential damage and contributes to the longevity of the pump.

5. Thermal Stability: The presence of oil in these pumps helps in dissipating heat generated during operation, contributing to their thermal stability. The oil absorbs and carries away heat, preventing excessive temperature rise within the pump. This thermal stability allows for consistent performance even during prolonged operation and helps protect the pump from overheating.

6. Noise Reduction: Oil-sealed vacuum pumps generally operate at lower noise levels compared to other types of vacuum pumps. The oil acts as a noise-damping medium, reducing the noise generated by the moving parts and the interaction of gases within the pump. This makes them suitable for applications where noise reduction is desired, such as laboratory environments or noise-sensitive industrial settings.

7. Versatility: Oil-sealed vacuum pumps are versatile and can handle a wide range of gases and vapors. They can effectively handle both condensable and non-condensable gases, making them suitable for diverse applications in industries such as chemical processing, pharmaceuticals, food processing, and research laboratories.

8. Cost-Effective: Oil-sealed vacuum pumps are often considered cost-effective options for many applications. They generally have a lower initial cost compared to some other types of high-vacuum pumps. Additionally, the maintenance and operating costs are relatively lower, making them an economical choice for industries that require reliable vacuum performance.

9. Simplicity and Ease of Maintenance: Oil-sealed vacuum pumps are relatively simple in design and easy to maintain. Routine maintenance typically involves monitoring oil levels, changing the oil periodically, and inspecting and replacing worn-out parts as necessary. The simplicity of maintenance procedures contributes to the overall cost-effectiveness and ease of operation.

10. Compatibility with Other Equipment: Oil-sealed vacuum pumps are compatible with various process equipment and systems. They can be easily integrated into existing setups or used in conjunction with other vacuum-related equipment, such as vacuum chambers, distillation systems, or industrial process equipment.

These advantages make oil-sealed vacuum pumps a popular choice in many industries where reliable, high-performance vacuum systems are required. However, it’s important to consider specific application requirements and consult with experts to determine the most suitable type of vacuum pump for a particular use case.

What Is the Role of Vacuum Pumps in Pharmaceutical Manufacturing?

Vacuum pumps play a crucial role in various aspects of pharmaceutical manufacturing. Here’s a detailed explanation:

Vacuum pumps are extensively used in pharmaceutical manufacturing processes to support a range of critical operations. Some of the key roles of vacuum pumps in pharmaceutical manufacturing include:

1. Drying and Evaporation: Vacuum pumps are employed in drying and evaporation processes within the pharmaceutical industry. They facilitate the removal of moisture or solvents from pharmaceutical products or intermediates. Vacuum drying chambers or evaporators utilize vacuum pumps to create low-pressure conditions, which lower the boiling points of liquids, allowing them to evaporate at lower temperatures. By applying vacuum, moisture or solvents can be efficiently removed from substances such as active pharmaceutical ingredients (APIs), granules, powders, or coatings, ensuring the desired product quality and stability.

2. Filtration and Filtrate Recovery: Vacuum pumps are used in filtration processes for the separation of solid-liquid mixtures. Vacuum filtration systems typically employ a filter medium, such as filter paper or membranes, to retain solids while allowing the liquid portion to pass through. By applying vacuum to the filtration apparatus, the liquid is drawn through the filter medium, leaving behind the solids. Vacuum pumps facilitate efficient filtration, speeding up the process and improving product quality. Additionally, vacuum pumps can aid in filtrate recovery by collecting and transferring the filtrate for further processing or reuse.

3. Distillation and Purification: Vacuum pumps are essential in distillation and purification processes within the pharmaceutical industry. Distillation involves the separation of liquid mixtures based on their different boiling points. By creating a vacuum environment, vacuum pumps lower the boiling points of the components, allowing them to vaporize and separate more easily. This enables efficient separation and purification of pharmaceutical compounds, including the removal of impurities or the isolation of specific components. Vacuum pumps are utilized in various distillation setups, such as rotary evaporators or thin film evaporators, to achieve precise control over the distillation conditions.

4. Freeze Drying (Lyophilization): Vacuum pumps are integral to the freeze drying process, also known as lyophilization. Lyophilization is a dehydration technique that involves the removal of water or solvents from pharmaceutical products while preserving their structure and integrity. Vacuum pumps create a low-pressure environment in freeze drying chambers, allowing the frozen product to undergo sublimation. During sublimation, the frozen water or solvent directly transitions from the solid phase to the vapor phase, bypassing the liquid phase. Vacuum pumps facilitate efficient and controlled sublimation, leading to the production of stable, shelf-stable pharmaceutical products with extended shelf life.

5. Tablet and Capsule Manufacturing: Vacuum pumps are utilized in tablet and capsule manufacturing processes. They are involved in the creation of vacuum within tablet presses or capsule filling machines. By applying vacuum, the air is removed from the die cavity or capsule cavity, allowing for the precise filling of powders or granules. Vacuum pumps contribute to the production of uniform and well-formed tablets or capsules by ensuring accurate dosing and minimizing air entrapment, which can affect the final product quality.

6. Sterilization and Decontamination: Vacuum pumps are employed in sterilization and decontamination processes within the pharmaceutical industry. Autoclaves and sterilizers utilize vacuum pumps to create a vacuum environment before introducing steam or chemical sterilants. By removing air or gases from the chamber, vacuum pumps assist in achieving effective sterilization or decontamination by enhancing the penetration and distribution of sterilants. Vacuum pumps also aid in the removal of sterilants and residues after the sterilization process is complete.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, dry screw pumps, or liquid ring pumps, may be utilized in pharmaceutical manufacturing depending on the specific requirements of the process and the compatibility with pharmaceutical products.

In summary, vacuum pumps play a vital role in various stages of pharmaceutical manufacturing, including drying and evaporation, filtration and filtrate recovery, distillation and purification, freeze drying (lyophilization), tablet and capsule manufacturing, as well as sterilization and decontamination. By enabling efficient and controlled processes, vacuum pumps contribute to the production of high-quality pharmaceutical products, ensuring the desired characteristics, stability, and safety.

Can Vacuum Pumps Be Used in Food Processing?

Yes, vacuum pumps are widely used in food processing for various applications. Here’s a detailed explanation:

Vacuum pumps play a crucial role in the food processing industry by enabling the creation and maintenance of vacuum or low-pressure environments. They offer several benefits in terms of food preservation, packaging, and processing. Here are some common applications of vacuum pumps in food processing: