Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

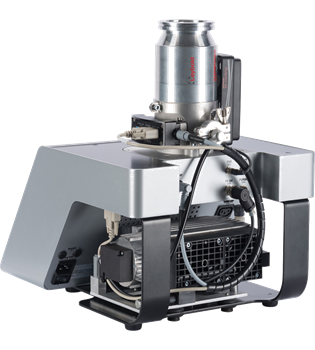

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used in the Aerospace Sector?

Vacuum pumps indeed have various applications in the aerospace sector. Here’s a detailed explanation:

Vacuum pumps play a crucial role in several areas of the aerospace industry, supporting various processes and systems. Some of the key applications of vacuum pumps in the aerospace sector include:

1. Space Simulation Chambers: Vacuum pumps are used in space simulation chambers to replicate the low-pressure conditions experienced in outer space. These chambers are utilized for testing and validating the performance and functionality of aerospace components and systems under simulated space conditions. Vacuum pumps create and maintain the necessary vacuum environment within these chambers, allowing engineers and scientists to evaluate the behavior and response of aerospace equipment in space-like conditions.

2. Propellant Management: In space propulsion systems, vacuum pumps are employed for propellant management. They help in the transfer, circulation, and pressurization of propellants, such as liquid rocket fuels or cryogenic fluids, in both launch vehicles and spacecraft. Vacuum pumps assist in creating the required pressure differentials for propellant flow and control, ensuring efficient and reliable operation of propulsion systems.

3. Environmental Control Systems: Vacuum pumps are utilized in the environmental control systems of aircraft and spacecraft. These systems are responsible for maintaining the desired atmospheric conditions, including temperature, humidity, and cabin pressure, to ensure the comfort, safety, and well-being of crew members and passengers. Vacuum pumps are used to regulate and control the cabin pressure, facilitating the circulation of fresh air and maintaining the desired air quality within the aircraft or spacecraft.

4. Satellite Technology: Vacuum pumps find numerous applications in satellite technology. They are used in the fabrication and testing of satellite components, such as sensors, detectors, and electronic devices. Vacuum pumps help create the necessary vacuum conditions for thin film deposition, surface treatment, and testing processes, ensuring the performance and reliability of satellite equipment. Additionally, vacuum pumps are employed in satellite propulsion systems to manage propellants and provide thrust for orbital maneuvers.

5. Avionics and Instrumentation: Vacuum pumps are involved in the production and testing of avionics and instrumentation systems used in aerospace applications. They facilitate processes such as thin film deposition, vacuum encapsulation, and vacuum drying, ensuring the integrity and functionality of electronic components and circuitry. Vacuum pumps are also utilized in vacuum leak testing, where they help create a vacuum environment to detect and locate any leaks in aerospace systems and components.

6. High Altitude Testing: Vacuum pumps are used in high altitude testing facilities to simulate the low-pressure conditions encountered at high altitudes. These testing facilities are employed for evaluating the performance and functionality of aerospace equipment, such as engines, materials, and structures, under simulated high altitude conditions. Vacuum pumps create and control the required low-pressure environment, allowing engineers and researchers to assess the behavior and response of aerospace systems in high altitude scenarios.

7. Rocket Engine Testing: Vacuum pumps are crucial in rocket engine testing facilities. They are utilized to evacuate and maintain the vacuum conditions in engine test chambers or nozzles during rocket engine testing. By creating a vacuum environment, these pumps simulate the conditions experienced by rocket engines in the vacuum of space, enabling accurate testing and evaluation of engine performance, thrust levels, and efficiency.

It’s important to note that aerospace applications often require specialized vacuum pumps capable of meeting stringent requirements, such as high reliability, low outgassing, compatibility with propellants or cryogenic fluids, and resistance to extreme temperatures and pressures.

In summary, vacuum pumps are extensively used in the aerospace sector for a wide range of applications, including space simulation chambers, propellant management, environmental control systems, satellite technology, avionics and instrumentation, high altitude testing, and rocket engine testing. They contribute to the development, testing, and operation of aerospace equipment, ensuring optimal performance, reliability, and safety.

What Is the Role of Vacuum Pumps in Pharmaceutical Manufacturing?

Vacuum pumps play a crucial role in various aspects of pharmaceutical manufacturing. Here’s a detailed explanation:

Vacuum pumps are extensively used in pharmaceutical manufacturing processes to support a range of critical operations. Some of the key roles of vacuum pumps in pharmaceutical manufacturing include:

1. Drying and Evaporation: Vacuum pumps are employed in drying and evaporation processes within the pharmaceutical industry. They facilitate the removal of moisture or solvents from pharmaceutical products or intermediates. Vacuum drying chambers or evaporators utilize vacuum pumps to create low-pressure conditions, which lower the boiling points of liquids, allowing them to evaporate at lower temperatures. By applying vacuum, moisture or solvents can be efficiently removed from substances such as active pharmaceutical ingredients (APIs), granules, powders, or coatings, ensuring the desired product quality and stability.

2. Filtration and Filtrate Recovery: Vacuum pumps are used in filtration processes for the separation of solid-liquid mixtures. Vacuum filtration systems typically employ a filter medium, such as filter paper or membranes, to retain solids while allowing the liquid portion to pass through. By applying vacuum to the filtration apparatus, the liquid is drawn through the filter medium, leaving behind the solids. Vacuum pumps facilitate efficient filtration, speeding up the process and improving product quality. Additionally, vacuum pumps can aid in filtrate recovery by collecting and transferring the filtrate for further processing or reuse.

3. Distillation and Purification: Vacuum pumps are essential in distillation and purification processes within the pharmaceutical industry. Distillation involves the separation of liquid mixtures based on their different boiling points. By creating a vacuum environment, vacuum pumps lower the boiling points of the components, allowing them to vaporize and separate more easily. This enables efficient separation and purification of pharmaceutical compounds, including the removal of impurities or the isolation of specific components. Vacuum pumps are utilized in various distillation setups, such as rotary evaporators or thin film evaporators, to achieve precise control over the distillation conditions.

4. Freeze Drying (Lyophilization): Vacuum pumps are integral to the freeze drying process, also known as lyophilization. Lyophilization is a dehydration technique that involves the removal of water or solvents from pharmaceutical products while preserving their structure and integrity. Vacuum pumps create a low-pressure environment in freeze drying chambers, allowing the frozen product to undergo sublimation. During sublimation, the frozen water or solvent directly transitions from the solid phase to the vapor phase, bypassing the liquid phase. Vacuum pumps facilitate efficient and controlled sublimation, leading to the production of stable, shelf-stable pharmaceutical products with extended shelf life.

5. Tablet and Capsule Manufacturing: Vacuum pumps are utilized in tablet and capsule manufacturing processes. They are involved in the creation of vacuum within tablet presses or capsule filling machines. By applying vacuum, the air is removed from the die cavity or capsule cavity, allowing for the precise filling of powders or granules. Vacuum pumps contribute to the production of uniform and well-formed tablets or capsules by ensuring accurate dosing and minimizing air entrapment, which can affect the final product quality.

6. Sterilization and Decontamination: Vacuum pumps are employed in sterilization and decontamination processes within the pharmaceutical industry. Autoclaves and sterilizers utilize vacuum pumps to create a vacuum environment before introducing steam or chemical sterilants. By removing air or gases from the chamber, vacuum pumps assist in achieving effective sterilization or decontamination by enhancing the penetration and distribution of sterilants. Vacuum pumps also aid in the removal of sterilants and residues after the sterilization process is complete.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, dry screw pumps, or liquid ring pumps, may be utilized in pharmaceutical manufacturing depending on the specific requirements of the process and the compatibility with pharmaceutical products.

In summary, vacuum pumps play a vital role in various stages of pharmaceutical manufacturing, including drying and evaporation, filtration and filtrate recovery, distillation and purification, freeze drying (lyophilization), tablet and capsule manufacturing, as well as sterilization and decontamination. By enabling efficient and controlled processes, vacuum pumps contribute to the production of high-quality pharmaceutical products, ensuring the desired characteristics, stability, and safety.

What Is the Purpose of a Vacuum Pump in an HVAC System?

In an HVAC (Heating, Ventilation, and Air Conditioning) system, a vacuum pump serves a crucial purpose. Here’s a detailed explanation:

The purpose of a vacuum pump in an HVAC system is to remove air and moisture from the refrigerant lines and the system itself. HVAC systems, particularly those that rely on refrigeration, operate under specific pressure and temperature conditions to facilitate the transfer of heat. To ensure optimal performance and efficiency, it is essential to evacuate any non-condensable gases, air, and moisture from the system.

Here are the key reasons why a vacuum pump is used in an HVAC system:

1. Removing Moisture: Moisture can be present within an HVAC system due to various factors, such as system installation, leaks, or improper maintenance. When moisture combines with the refrigerant, it can cause issues like ice formation, reduced system efficiency, and potential damage to system components. A vacuum pump helps remove moisture by creating a low-pressure environment, which causes the moisture to boil and turn into vapor, effectively evacuating it from the system.

2. Eliminating Air and Non-Condensable Gases: Air and non-condensable gases, such as nitrogen or oxygen, can enter an HVAC system during installation, repair, or through leaks. These gases can hinder the refrigeration process, affect heat transfer, and decrease system performance. By using a vacuum pump, technicians can evacuate the air and non-condensable gases, ensuring that the system operates with the designed refrigerant and pressure levels.

3. Preparing for Refrigerant Charging: Prior to charging the HVAC system with refrigerant, it is crucial to create a vacuum to remove any contaminants and ensure the system is clean and ready for optimal refrigerant circulation. By evacuating the system with a vacuum pump, technicians ensure that the refrigerant enters a clean and controlled environment, reducing the risk of system malfunctions and improving overall efficiency.

4. Leak Detection: Vacuum pumps are also used in HVAC systems for leak detection purposes. After evacuating the system, technicians can monitor the pressure to check if it holds steady. A significant drop in pressure indicates the presence of leaks, enabling technicians to identify and repair them before charging the system with refrigerant.

In summary, a vacuum pump plays a vital role in an HVAC system by removing moisture, eliminating air and non-condensable gases, preparing the system for refrigerant charging, and aiding in leak detection. These functions help ensure optimal system performance, energy efficiency, and longevity, while also reducing the risk of system malfunctions and damage.

editor by Dream 2024-05-14

China best Air Cooled Screw Vacuum Pumps for Soap and Synthetic Detergents vacuum pump design

Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

What Are the Advantages of Using Oil-Sealed Vacuum Pumps?

Oil-sealed vacuum pumps offer several advantages in various applications. Here’s a detailed explanation:

1. High Vacuum Performance: Oil-sealed vacuum pumps are known for their ability to achieve high levels of vacuum. They can create and maintain deep vacuum levels, making them suitable for applications that require a low-pressure environment. The use of oil as a sealing and lubricating medium helps in achieving efficient vacuum performance.

2. Wide Operating Range: Oil-sealed vacuum pumps have a wide operating range, allowing them to handle a broad spectrum of vacuum levels. They can operate effectively in both low-pressure and high-vacuum conditions, making them versatile for different applications across various industries.

3. Efficient and Reliable Operation: These pumps are known for their reliability and consistent performance. The oil-sealed design provides effective sealing, preventing air leakage and maintaining a stable vacuum level. They are designed to operate continuously for extended periods without significant performance degradation, making them suitable for continuous industrial processes.

4. Contamination Handling: Oil-sealed vacuum pumps are effective in handling certain types of contaminants that may be present in the process gases or air being evacuated. The oil acts as a barrier, trapping and absorbing certain particulates, moisture, and chemical vapors, preventing them from reaching the pump mechanism. This helps protect the pump internals from potential damage and contributes to the longevity of the pump.

5. Thermal Stability: The presence of oil in these pumps helps in dissipating heat generated during operation, contributing to their thermal stability. The oil absorbs and carries away heat, preventing excessive temperature rise within the pump. This thermal stability allows for consistent performance even during prolonged operation and helps protect the pump from overheating.

6. Noise Reduction: Oil-sealed vacuum pumps generally operate at lower noise levels compared to other types of vacuum pumps. The oil acts as a noise-damping medium, reducing the noise generated by the moving parts and the interaction of gases within the pump. This makes them suitable for applications where noise reduction is desired, such as laboratory environments or noise-sensitive industrial settings.

7. Versatility: Oil-sealed vacuum pumps are versatile and can handle a wide range of gases and vapors. They can effectively handle both condensable and non-condensable gases, making them suitable for diverse applications in industries such as chemical processing, pharmaceuticals, food processing, and research laboratories.

8. Cost-Effective: Oil-sealed vacuum pumps are often considered cost-effective options for many applications. They generally have a lower initial cost compared to some other types of high-vacuum pumps. Additionally, the maintenance and operating costs are relatively lower, making them an economical choice for industries that require reliable vacuum performance.

9. Simplicity and Ease of Maintenance: Oil-sealed vacuum pumps are relatively simple in design and easy to maintain. Routine maintenance typically involves monitoring oil levels, changing the oil periodically, and inspecting and replacing worn-out parts as necessary. The simplicity of maintenance procedures contributes to the overall cost-effectiveness and ease of operation.

10. Compatibility with Other Equipment: Oil-sealed vacuum pumps are compatible with various process equipment and systems. They can be easily integrated into existing setups or used in conjunction with other vacuum-related equipment, such as vacuum chambers, distillation systems, or industrial process equipment.

These advantages make oil-sealed vacuum pumps a popular choice in many industries where reliable, high-performance vacuum systems are required. However, it’s important to consider specific application requirements and consult with experts to determine the most suitable type of vacuum pump for a particular use case.

Can Vacuum Pumps Be Used in the Production of Solar Panels?

Yes, vacuum pumps are extensively used in the production of solar panels. Here’s a detailed explanation:

Solar panels, also known as photovoltaic (PV) panels, are devices that convert sunlight into electricity. The manufacturing process of solar panels involves several critical steps, many of which require the use of vacuum pumps. Vacuum technology plays a crucial role in ensuring the efficiency, reliability, and quality of solar panel production. Here are some key areas where vacuum pumps are utilized:

1. Silicon Ingot Production: The first step in solar panel manufacturing is the production of silicon ingots. These ingots are cylindrical blocks of pure crystalline silicon that serve as the raw material for solar cells. Vacuum pumps are used in the Czochralski process, which involves melting polycrystalline silicon in a quartz crucible and then slowly pulling a single crystal ingot from the molten silicon. Vacuum pumps create a controlled environment by removing impurities and preventing contamination during the crystal growth process.

2. Wafering: After the silicon ingots are produced, they undergo wafering, where the ingots are sliced into thin wafers. Vacuum pumps are used in wire saws to create a low-pressure environment that helps to cool and lubricate the cutting wire. The vacuum also assists in removing the silicon debris generated during the slicing process, ensuring clean and precise cuts.

3. Solar Cell Production: Vacuum pumps play a significant role in various stages of solar cell production. Solar cells are the individual units within a solar panel that convert sunlight into electricity. Vacuum pumps are used in the following processes:

– Diffusion: In the diffusion process, dopants such as phosphorus or boron are introduced into the silicon wafer to create the desired electrical properties. Vacuum pumps are utilized in the diffusion furnace to create a controlled atmosphere for the diffusion process and remove any impurities or gases that may affect the quality of the solar cell.

– Deposition: Thin films of materials such as anti-reflective coatings, passivation layers, and electrode materials are deposited onto the silicon wafer. Vacuum pumps are used in various deposition techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD) to create the necessary vacuum conditions for precise and uniform film deposition.

– Etching: Etching processes are employed to create the desired surface textures on the solar cell, which enhance light trapping and improve efficiency. Vacuum pumps are used in plasma etching or wet etching techniques to remove unwanted material or create specific surface structures on the solar cell.

4. Encapsulation: After the solar cells are produced, they are encapsulated to protect them from environmental factors such as moisture and mechanical stress. Vacuum pumps are used in the encapsulation process to create a vacuum environment, ensuring the removal of air and moisture from the encapsulation materials. This helps to achieve proper bonding and prevents the formation of bubbles or voids, which could degrade the performance and longevity of the solar panel.

5. Testing and Quality Control: Vacuum pumps are also utilized in testing and quality control processes during solar panel production. For example, vacuum systems can be used for leak testing to ensure the integrity of the encapsulation and to detect any potential defects or leaks in the panel assembly. Vacuum-based measurement techniques may also be employed for assessing the electrical characteristics and efficiency of the solar cells or panels.

In summary, vacuum pumps are integral to the production of solar panels. They are used in various stages of the manufacturing process, including silicon ingot production, wafering, solar cell production (diffusion, deposition, and etching), encapsulation, and testing. Vacuum technology enables precise control, contamination prevention, and efficient processing, contributing to the production of high-quality and reliable solar panels.

Are There Different Types of Vacuum Pumps Available?

Yes, there are various types of vacuum pumps available, each designed to suit specific applications and operating principles. Here’s a detailed explanation:

Vacuum pumps are classified based on their operating principles, mechanisms, and the type of vacuum they can generate. Some common types of vacuum pumps include:

1. Rotary Vane Vacuum Pumps:

– Description: Rotary vane pumps are positive displacement pumps that use rotating vanes to create a vacuum. The vanes slide in and out of slots in the pump rotor, trapping and compressing gas to create suction and generate a vacuum.

– Applications: Rotary vane vacuum pumps are widely used in applications requiring moderate vacuum levels, such as laboratory vacuum systems, packaging, refrigeration, and air conditioning.

2. Diaphragm Vacuum Pumps:

– Description: Diaphragm pumps use a flexible diaphragm that moves up and down to create a vacuum. The diaphragm separates the vacuum chamber from the driving mechanism, preventing contamination and oil-free operation.

– Applications: Diaphragm vacuum pumps are commonly used in laboratories, medical equipment, analysis instruments, and applications where oil-free or chemical-resistant vacuum is required.

3. Scroll Vacuum Pumps:

– Description: Scroll pumps have two spiral-shaped scrolls—one fixed and one orbiting—which create a series of moving crescent-shaped gas pockets. As the scrolls move, gas is continuously trapped and compressed, resulting in a vacuum.

– Applications: Scroll vacuum pumps are suitable for applications requiring a clean and dry vacuum, such as analytical instruments, vacuum drying, and vacuum coating.

4. Piston Vacuum Pumps:

– Description: Piston pumps use reciprocating pistons to create a vacuum by compressing gas and then releasing it through valves. They can achieve high vacuum levels but may require lubrication.

– Applications: Piston vacuum pumps are used in applications requiring high vacuum levels, such as vacuum furnaces, freeze drying, and semiconductor manufacturing.

5. Turbo Molecular Vacuum Pumps:

– Description: Turbo pumps use high-speed rotating blades or impellers to create a molecular flow, continuously pumping gas molecules out of the system. They typically require a backing pump to operate.

– Applications: Turbo molecular pumps are used in high vacuum applications, such as semiconductor fabrication, research laboratories, and mass spectrometry.

6. Diffusion Vacuum Pumps:

– Description: Diffusion pumps rely on the diffusion of gas molecules and their subsequent removal by a high-speed jet of vapor. They operate at high vacuum levels and require a backing pump.

– Applications: Diffusion pumps are commonly used in applications requiring high vacuum levels, such as vacuum metallurgy, space simulation chambers, and particle accelerators.

7. Cryogenic Vacuum Pumps:

– Description: Cryogenic pumps use extremely low temperatures to condense and capture gas molecules, creating a vacuum. They rely on cryogenic fluids, such as liquid nitrogen or helium, for operation.

– Applications: Cryogenic vacuum pumps are used in ultra-high vacuum applications, such as particle physics research, material science, and fusion reactors.

These are just a few examples of the different types of vacuum pumps available. Each type has its advantages, limitations, and suitability for specific applications. The choice of vacuum pump depends on factors like required vacuum level, gas compatibility, reliability, cost, and the specific needs of the application.

editor by Dream 2024-05-13

China Best Sales Compressed Air Diaphragm Pump Water Transfer Pneumatic Diaphragm Pump for Chemical vacuum pump booster

Product Description

Product Description

2BE series water ring vacuum pump and compressor, based on many years of scientific research results and production experience, combined with the international advanced technology of similar products, developed high efficiency and energy saving products, usually used for pumping no CHINAMFG particles, insoluble in water, no corrosion gas, in order to form a vacuum and pressure in a closed container. By changing the structure material, it can also be used to suck corrosive gas or to use corrosive liquid as working fluid. Widely used in papermaking, chemical, petrochemical, light industry, pharmaceutical, food, metallurgy, building materials, electrical appliances, coal washing, mineral processing, chemical fertilizer and other industries.

This series of pumps uses the CHINAMFG single action structure, has the advantages of simple structure, convenient maintenance, reliable operation, high efficiency and energy saving, and can adapt to large displacement, load impact fluctuation and other harsh conditions.

The key components, such as the distribution plate, impeller and pump shaft, have been optimized to simplify the structure, improve the performance and achieve energy saving. The welding impeller is used, the blade is pressed and formed once, and the shape line is reasonable; Hub processing, fundamentally solve the dynamic balance problem. Impeller and pump shaft are fitted with hot filling interference, reliable performance. It runs smoothly. After the impeller is welded, the whole is subjected to good heat treatment, and the blade has good toughness, so that the impact resistance and bending resistance of the blade can be fundamentally guaranteed, and it can adapt to the bad working conditions of load impact fluctuation.

2BE series pump, with air and water separator, multi-position exhaust port, pump cover is provided with exhaust valve overhaul window, impeller and distribution plate clearance through positioning bearing gland at both ends of the adjustment, easy to install and use, simple operation, easy maintenance.

Pump structure

The performance curve of this series of pumps is measured under the following working conditions: the suction medium is 20°C saturated air, the working liquid temperature is 15°C, the exhaust pressure is 1013mbar, and the deviation of soil is 10%.

Structure declaration

2BEA-10-25 Structure diagram

1.Flat key 2. Shaft 3. Oil deflector 4. Bearing cap 5. Bearings 6. Bearing bracket 7.Brasque cover

8.Brasque body 9. Brasque ring 10. Brasque 11.Valve plate 12. Valve block

13.Front distribution plate 14.Pump body 15. Impeller 16. O seal ring.

17.Back distribution plate 18. Side cover. 19. Flat key 20. Axle sleeve 21. Elastic collar

22.Water retaining ring 23. Adjusting washer 24. Rear bearing body 25. Bearing screw cap

26.Bearing 27. Bolt

2BEA-30-70 Structure diagram

1.Flat key 2. Shaft 3. Oil deflector 4. Front bearing retainer 5. Front bearing body

6. Front bearing inner cover 7. Front side cover 8. Brasque cover 9. Brasque body 10. Brasque ring

11. Brasque 12. Front distribution plate 13. Pump body 14. Impeller 15. O seal ring

16. Valve block 17. Valve plate 18. Back distribution plate 19. Axle sleeve 20. Flat key

21. Back side cover 22. Water retaining ring 23. Rear bearing inner cover 24. Bearing

25. Adjusting washer 26. Oil block 27. Rear bearing outer cover 28. Back bearing body

29. Oil baffle disc 30. Elastic retainer or circular spiral

Product Parameters

| Model | 2BEA SERIES | |

| Minimum suction absolute pressure (hPa) | 33-160 | |

| Suction intensity(m³/min) | Absolute inhalation capacity 60hPa | 3,95-336 |

| Absolute inhalation capacity 100hPa | 4.58-342 | |

| Absolute inhalation capacity 200hPa | 4.87-352 | |

| Absolute inhalation capacity 400hPa | 4.93-353 | |

| Max. shaft power(kw) | 7-453 | |

| Motor power(kw) | 11-560 | |

| Speed(rpm) | 197-1750 | |

| Weight(kg) | 235-11800 | |

| Size | 795*375*355mm-3185*2110*2045mm | |

| Model | 2BEC SERIES | |

| Minimum suction absolute pressure (hPa) | 160 | |

| Suction intensity(m³/min) | Absolute inhalation capacity 60hPa | 63-1700 |

| Absolute inhalation capacity 100hPa | 64-1738 | |

| Absolute inhalation capacity 200hPa | 65-1785 | |

| Absolute inhalation capacity 400hPa | 67-1800 | |

| Absolute inhalation capacity 550hPa | 68-1830 | |

| Max. shaft power(kw) | 61-2100 | |

| Motor power(kw) | 75-2240 | |

| Speed(rpm) | 105-610 | |

| Weight(kg) | 2930-57500 | |

| Size | 2102*1320*1160mm-5485*3560*3400mm | |

Detailed Photos

Operation site

Company presentation

Product gallery

RFQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral export wooden case . If you have legally registered patent, we can pack the goods in

wooden case with your own marks after getting your authorization letters.

Q2. What is your termsof payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, etc.

Q4. How about your delivery time?

A: Generally, it will take from 10 dasys to 30 days after receiving your advance payment according to the pump’s material. The

specific delivery time also depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test the pumps before delivery .

Q8: How do you make our business long-term and good relationship?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they are from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online |

|---|---|

| Warranty: | 1 Years |

| Oil or Not: | Oil Free |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Kinetic Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

What safety features are typically integrated into diaphragm vacuum pump systems?

Diaphragm vacuum pump systems typically incorporate various safety features to ensure safe operation and protect both the users and the equipment. Here’s a detailed explanation:

1. Overpressure Protection: Diaphragm vacuum pump systems often include overpressure protection mechanisms to prevent excessive pressure buildup. These mechanisms can be in the form of pressure relief valves or pressure sensors that automatically shut off the pump or release excess pressure if it exceeds the predefined limits. Overpressure protection safeguards the system from potential damage and reduces the risk of accidents or equipment failure.

2. Thermal Protection: Thermal protection features are designed to prevent the pump from overheating. Diaphragm pumps can generate heat during operation, especially in continuous or intensive use. Thermal protection mechanisms, such as thermal switches or temperature sensors, monitor the pump’s temperature and automatically shut it down or activate cooling systems if the temperature exceeds safe limits. This helps prevent damage to the pump and reduces the risk of fire or other safety hazards.

3. Leak Detection: Diaphragm vacuum pump systems may incorporate leak detection mechanisms to alert users in case of any air or gas leakage. These mechanisms can include pressure sensors or flow sensors that monitor the system’s integrity. If a leak is detected, visual or audible alarms may be triggered, indicating the need for immediate attention and repair to maintain the system’s efficiency and prevent the release of potentially harmful substances into the environment.

4. Electrical Safety: Diaphragm pump systems have electrical safety features to protect against electrical hazards. This includes measures such as ground fault circuit interrupters (GFCI) or residual current devices (RCD) that detect and interrupt electrical faults, preventing electric shocks or short circuits. Proper grounding and insulation of electrical components are also important safety considerations in diaphragm pump systems.

5. Emergency Stop: Many diaphragm pump systems are equipped with an emergency stop button or switch that allows users to quickly shut down the pump in case of an emergency or hazardous situation. The emergency stop feature provides a convenient and immediate means to halt pump operation, ensuring the safety of the users and preventing further risks or damages.

6. System Monitoring and Alarms: Advanced diaphragm pump systems may incorporate monitoring features that continuously assess the system’s performance and provide real-time feedback. This can include monitoring parameters such as vacuum levels, temperature, pressure, or flow rates. Alarms or visual indicators are often integrated to alert users in case of deviations from normal operating conditions, enabling prompt corrective actions and preventing potential safety issues.

It’s important to note that the specific safety features integrated into diaphragm vacuum pump systems may vary depending on the manufacturer, model, and intended application. Users should carefully review the product documentation and follow the manufacturer’s instructions regarding safety precautions, installation requirements, and maintenance procedures to ensure safe and proper use of the equipment.

In summary, diaphragm vacuum pump systems typically incorporate safety features such as overpressure protection, thermal protection, leak detection, electrical safety measures, emergency stop functionalities, and system monitoring with alarms. These safety features aim to protect users, prevent equipment damage, and ensure the safe and reliable operation of the diaphragm pump system.

Are there variations in diaphragm vacuum pump designs, and how do they affect performance?

Yes, there are variations in diaphragm vacuum pump designs, and these variations can affect the performance of the pumps. Here’s a detailed explanation:

Diaphragm vacuum pumps are available in different designs and configurations to meet specific application requirements. The design variations can impact several aspects of the pump’s performance, including:

– Pump Construction: Diaphragm vacuum pumps can have single or multiple diaphragms. Single diaphragm pumps typically offer a compact and lightweight design, making them suitable for portable applications. Multiple diaphragm pumps, on the other hand, provide higher flow rates and enhanced performance for applications that require greater pumping capacity.

– Materials of Construction: Diaphragm pumps can be constructed using various materials, including metals, plastics, and elastomers. The choice of materials affects the pump’s chemical compatibility, resistance to corrosion or abrasion, and overall durability. Selecting the appropriate materials is crucial to ensure reliable pump performance in specific operating conditions.

– Valve Design: The valves in diaphragm vacuum pumps play a critical role in controlling the direction of air flow and maintaining efficient pumping. Variations in valve design, such as the type of valves used (e.g., flapper valves, reed valves) and their configuration, can impact the pump’s suction capacity, vacuum level, and overall efficiency.

– Sealing Mechanisms: Diaphragm pumps employ various sealing mechanisms to ensure airtight operation and prevent air leakage. The sealing mechanisms can differ in terms of design, materials used, and effectiveness. Well-designed sealing mechanisms are necessary to maintain a consistent vacuum level and prevent loss of suction during operation.

– Control Features: Advanced diaphragm vacuum pumps may incorporate control features such as variable speed drives, pressure sensors, or automated systems for monitoring and adjusting pump performance. These control features can improve the pump’s efficiency, optimize energy consumption, and provide greater control over vacuum levels and flow rates.

The specific design variations in diaphragm vacuum pumps are often tailored to meet different application requirements, such as laboratory research, medical devices, or industrial processes. Therefore, it’s essential to consider the intended application and select a pump design that aligns with the desired performance parameters.

In summary, diaphragm vacuum pumps come in various designs and configurations that can impact their performance. Factors such as pump construction, materials of construction, valve design, sealing mechanisms, and control features all contribute to the overall efficiency, reliability, and suitability of the pump for specific applications.

What are the key components of a diaphragm vacuum pump?

A diaphragm vacuum pump consists of several key components that work together to create vacuum or low-pressure conditions. Here’s a detailed explanation of these components:

1. Diaphragm:

The diaphragm is the central component of a diaphragm vacuum pump. It is a flexible membrane that moves back and forth within a chamber to generate the pumping action. The diaphragm is typically made of a durable, chemically resistant material such as rubber or elastomer. It is responsible for creating changes in the chamber volume, resulting in suction and compression of gases.

2. Pumping Chamber:

The pumping chamber houses the diaphragm and provides the space for the diaphragm’s movement. It is a sealed chamber that expands and contracts as the diaphragm flexes. The pumping chamber is designed to be gas-tight to prevent leakage and maintain the vacuum or low-pressure conditions.

3. Inlet and Outlet Valves:

Diaphragm vacuum pumps typically have inlet and outlet valves that control the flow of gases into and out of the pumping chamber.

– Inlet Valve: The inlet valve allows gas or vapor to enter the pumping chamber during the suction phase. It opens when the diaphragm moves downward, creating a low-pressure region within the chamber.

– Outlet Valve: The outlet valve allows the compressed gas to be expelled from the pumping chamber during the compression and exhaust phases. It opens when the diaphragm moves upward, compressing the gas and forcing it out of the chamber.

4. Drive Mechanism:

The drive mechanism provides the motion and power to move the diaphragm back and forth within the pumping chamber. It can be an electric motor, a pneumatic actuator, or other mechanisms depending on the pump design. The drive mechanism ensures the continuous operation of the diaphragm, creating the pumping action.

5. Check Valves:

Check valves, also known as one-way valves or non-return valves, are often incorporated into diaphragm vacuum pumps to ensure the flow of gas occurs in the desired direction.

– Inlet Check Valve: The inlet check valve allows gas to enter the pumping chamber during the suction phase but prevents backflow when the diaphragm moves upward during compression and exhaust phases.

– Outlet Check Valve: The outlet check valve allows the compressed gas to be expelled from the pumping chamber during the compression and exhaust phases but prevents backflow into the chamber during the suction phase.

6. Housing and Mounting:

The housing of a diaphragm vacuum pump encloses and protects the internal components. It is typically made of a sturdy material such as metal or plastic. The housing also provides mounting points for the pump, allowing it to be securely installed in various orientations or integrated into larger systems.

7. Control and Monitoring Features:

Some diaphragm vacuum pumps may include control and monitoring features such as power switches, pressure gauges, or digital interfaces. These features allow for convenient operation, monitoring of vacuum levels, and integration with control systems or automation.

It’s important to note that the specific design and configuration of diaphragm vacuum pumps may vary across different manufacturers and models. Consulting the manufacturer’s specifications and documentation will provide detailed information on the components, construction, and performance characteristics of a particular diaphragm pump.

The combination of the diaphragm, pumping chamber, valves, drive mechanism, check valves, housing, and control features enables diaphragm vacuum pumps to generate efficient and reliable vacuum or low-pressure conditions for a wide range of applications.

editor by Dream 2024-05-10

China best Max Airflow 98 M³ /H High Pressure Air Blower Vacuum Pump 0.45 Kw Oil-Free Rotary Vane Pump for CNC vacuum pump oil near me

Product Description

Product Description

|

Pressure |

High Pressure |

|

Structure |

Single-stage Pump |

|

Outlet Size |

As customer request |

|

Voltage |

220V/380V/440V/As customer request |

|

Power |

0.45KW |

|

motor |

0.45 kw |

|

Max. Pressure |

300mbar /280mbar |

|

Max airflow: |

530m3/h 620m3/h |

|

Noise: |

70 dB(A) |

|

Certification |

CE |

|

Max Vacuum |

-300mbar |

|

Ring Blowers |

Oil-free |

|

Model number |

Frequency |

Rated Power |

Voltage |

Current |

Max airflow |

Max vacuum |

Max pressure |

|

2LG210-7AA11 |

50 Hz |

0.37 kw |

220 v |

2.7 A |

80 m³/h |

-120 mbar |

130 mbar |

|

60 Hz |

0.45 kw |

220 v |

3.2 A |

98 m³/h |

-150 mbar |

160 mbar |

application

Packaging & Shipping

Company Profile

Related product

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil Free |

| Structure: | Single-Stage Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Samples: |

US$ 450/Piece

1 Piece(Min.Order) | |

|---|

Can Vacuum Pumps Be Used in the Automotive Industry?

Yes, vacuum pumps are widely used in the automotive industry for various applications. Here’s a detailed explanation:

The automotive industry relies on vacuum pumps for several critical functions and systems within vehicles. Vacuum pumps play a crucial role in enhancing performance, improving fuel efficiency, and enabling the operation of various automotive systems. Here are some key applications of vacuum pumps in the automotive industry:

1. Brake Systems: Vacuum pumps are commonly used in vacuum-assisted brake systems, also known as power brakes. These systems utilize vacuum pressure to amplify the force applied by the driver to the brake pedal, making braking more efficient and responsive. Vacuum pumps help generate the required vacuum for power brake assistance, ensuring reliable and consistent braking performance.

2. Emission Control Systems: Vacuum pumps are integral components of emission control systems in vehicles. They assist in operating components such as the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system. Vacuum pumps help create the necessary vacuum conditions for proper functioning of these systems, reducing harmful emissions and improving overall environmental performance.

3. HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems in vehicles often utilize vacuum pumps for various functions. Vacuum pumps help control the vacuum-operated actuators that regulate the direction, temperature, and airflow of the HVAC system. They ensure efficient operation and precise control of the vehicle’s interior climate control system.

4. Turbocharger and Supercharger Systems: In performance-oriented vehicles, turbocharger and supercharger systems are used to increase engine power and efficiency. Vacuum pumps play a role in these systems by providing vacuum pressure for actuating wastegates, blow-off valves, and other control mechanisms. These components help regulate the boost pressure and ensure optimal performance of the forced induction system.

5. Fuel Delivery Systems: Vacuum pumps are employed in certain types of fuel delivery systems, such as mechanical fuel pumps. These pumps utilize vacuum pressure to draw fuel from the fuel tank and deliver it to the engine. While mechanical fuel pumps are less commonly used in modern vehicles, vacuum pumps are still found in some specialized applications.

6. Engine Management Systems: Vacuum pumps are utilized in engine management systems for various functions. They assist in operating components such as vacuum-operated actuators, vacuum reservoirs, and vacuum sensors. These components play a role in engine performance, emissions control, and overall system functionality.

7. Fluid Control Systems: Vacuum pumps are used in fluid control systems within vehicles, such as power steering systems. Vacuum-assisted power steering systems utilize vacuum pressure to assist the driver in steering, reducing the effort required. Vacuum pumps provide the necessary vacuum for power steering assistance, enhancing maneuverability and driver comfort.

8. Diagnostic and Testing Equipment: Vacuum pumps are also utilized in automotive diagnostic and testing equipment. These pumps create vacuum conditions necessary for testing and diagnosing various vehicle systems, such as intake manifold leaks, brake system integrity, and vacuum-operated components.

It’s important to note that different types of vacuum pumps may be used depending on the specific automotive application. Common vacuum pump technologies in the automotive industry include diaphragm pumps, rotary vane pumps, and electric vacuum pumps.

In summary, vacuum pumps have numerous applications in the automotive industry, ranging from brake systems and emission control to HVAC systems and engine management. They contribute to improved safety, fuel efficiency, environmental performance, and overall vehicle functionality.

What Is the Difference Between Dry and Wet Vacuum Pumps?

Dry and wet vacuum pumps are two distinct types of pumps that differ in their operating principles and applications. Here’s a detailed explanation of the differences between them:

Dry Vacuum Pumps:

Dry vacuum pumps operate without the use of any lubricating fluid or sealing water in the pumping chamber. They rely on non-contact mechanisms to create a vacuum. Some common types of dry vacuum pumps include:

1. Rotary Vane Pumps: Rotary vane pumps consist of a rotor with vanes that slide in and out of slots in the rotor. The rotation of the rotor creates chambers that expand and contract, allowing the gas to be pumped. The vanes and the housing are designed to create a seal, preventing gas from flowing back into the pump. Rotary vane pumps are commonly used in laboratories, medical applications, and industrial processes where a medium vacuum level is required.

2. Dry Screw Pumps: Dry screw pumps use two or more intermeshing screws to compress and transport gas. As the screws rotate, the gas is trapped between the threads and transported from the suction side to the discharge side. Dry screw pumps are known for their high pumping speeds, low noise levels, and ability to handle various gases. They are used in applications such as semiconductor manufacturing, chemical processing, and vacuum distillation.

3. Claw Pumps: Claw pumps use two rotors with claw-shaped lobes that rotate in opposite directions. The rotation creates a series of expanding and contracting chambers, enabling gas capture and pumping. Claw pumps are known for their oil-free operation, high pumping speeds, and suitability for handling dry and clean gases. They are commonly used in applications such as automotive manufacturing, food packaging, and environmental technology.

Wet Vacuum Pumps:

Wet vacuum pumps, also known as liquid ring pumps, operate by using a liquid, typically water, to create a seal and generate a vacuum. The liquid ring serves as both the sealing medium and the working fluid. Wet vacuum pumps are commonly used in applications where a higher level of vacuum is required or when handling corrosive gases. Some key features of wet vacuum pumps include:

1. Liquid Ring Pumps: Liquid ring pumps feature an impeller with blades that rotate eccentrically within a cylindrical casing. As the impeller rotates, the liquid forms a ring against the casing due to centrifugal force. The liquid ring creates a seal, and as the impeller spins, the volume of the gas chamber decreases, leading to the compression and discharge of gas. Liquid ring pumps are known for their ability to handle wet and corrosive gases, making them suitable for applications such as chemical processing, oil refining, and wastewater treatment.

2. Water Jet Pumps: Water jet pumps utilize a jet of high-velocity water to create a vacuum. The water jet entrains gases, and the mixture is then separated in a venturi section, where the water is recirculated, and the gases are discharged. Water jet pumps are commonly used in laboratories and applications where a moderate vacuum level is required.

The main differences between dry and wet vacuum pumps can be summarized as follows:

1. Operating Principle: Dry vacuum pumps operate without the need for any sealing fluid, while wet vacuum pumps utilize a liquid ring or water as a sealing and working medium.

2. Lubrication: Dry vacuum pumps do not require lubrication since there is no contact between moving parts, whereas wet vacuum pumps require the presence of a liquid for sealing and lubrication.

3. Applications: Dry vacuum pumps are suitable for applications where a medium vacuum level is required, and oil-free operation is desired. They are commonly used in laboratories, medical settings, and various industrial processes. Wet vacuum pumps, on the other hand, are used when a higher vacuum level is needed or when handling corrosive gases. They find applications in chemical processing, oil refining, and wastewater treatment, among others.

It’s important to note that the selection of a vacuum pump depends on specific requirements such as desired vacuum level, gas compatibility, operating conditions, and the nature of the application.

In summary, the primary distinction between dry and wet vacuum pumps lies in their operating principles, lubrication requirements, and applications. Dry vacuum pumps operate without any lubricating fluid, while wet vacuum pumps rely on a liquid ring or water for sealing and lubrication. The choice between dry and wet vacuum pumps depends on the specific needs of the application and the desired vacuum level.

What Industries Commonly Rely on Vacuum Pump Technology?

Vacuum pump technology finds applications in various industries where creating and controlling vacuum or low-pressure environments is crucial. Here’s a detailed explanation:

1. Manufacturing and Production: Vacuum pumps are extensively used in manufacturing and production processes across multiple industries. They are employed for tasks such as vacuum molding, vacuum packaging, vacuum degassing, vacuum drying, and vacuum distillation. Industries like automotive, aerospace, electronics, pharmaceuticals, and food processing rely on vacuum pump technology to achieve precise and controlled manufacturing conditions.

2. Chemical and Pharmaceutical: The chemical and pharmaceutical industries heavily rely on vacuum pumps for numerous applications. These include solvent recovery, vacuum filtration, vacuum drying, distillation, crystallization, and evaporation. Vacuum pumps enable these industries to carry out critical processes under reduced pressure, ensuring efficient separation, purification, and synthesis of various chemical compounds and pharmaceutical products.

3. Semiconductor and Electronics: The semiconductor and electronics industries extensively use vacuum pumps for manufacturing microchips, electronic components, and electronic devices. Vacuum pumps are crucial in processes such as physical vapor deposition (PVD), chemical vapor deposition (CVD), etching, ion implantation, and sputtering. These processes require controlled vacuum conditions to ensure precise deposition, surface modification, and contamination-free manufacturing.

4. Research and Development: Vacuum pump technology is integral to research and development activities across scientific disciplines. It supports experiments and investigations in fields such as physics, chemistry, materials science, biology, and environmental science. Vacuum pumps facilitate processes like freeze drying, vacuum distillation, vacuum evaporation, vacuum spectroscopy, and creating controlled atmospheric conditions for studying various phenomena.

5. Food and Beverage: The food and beverage industry relies on vacuum pumps for packaging and preservation purposes. Vacuum sealing is used to extend the shelf life of food products by removing air and creating a vacuum-sealed environment that inhibits spoilage and maintains freshness. Vacuum pumps are also used in processes like freeze drying, vacuum concentration, and vacuum cooling.

6. Oil and Gas: In the oil and gas industry, vacuum pumps play a role in various applications. They are used for crude oil vacuum distillation, vacuum drying, vapor recovery, gas compression, and gas stripping processes. Vacuum pumps help maintain optimal conditions during oil refining, gas processing, and petrochemical manufacturing.

7. Environmental and Waste Management: Vacuum pumps are employed in environmental and waste management applications. They are used for tasks such as soil vapor extraction, groundwater remediation, landfill gas recovery, and wastewater treatment. Vacuum pumps facilitate the removal and containment of gases, vapors, and pollutants, contributing to environmental protection and sustainable waste management.

8. Medical and Healthcare: The medical and healthcare sectors utilize vacuum pumps for various purposes. They are used in medical equipment such as vacuum-assisted wound therapy devices, vacuum-based laboratory analyzers, and vacuum suction systems in hospitals and clinics. Vacuum pumps are also used in medical research, pharmaceutical production, and medical device manufacturing.

9. Power Generation: Vacuum pumps play a role in power generation industries, including nuclear power plants and thermal power plants. They are used for steam condensation, turbine blade cooling, vacuum drying during transformer manufacturing, and vacuum systems for testing and maintenance of power plant equipment.

10. HVAC and Refrigeration: The HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries rely on vacuum pumps for system installation, maintenance, and repair. Vacuum pumps are used to evacuate air and moisture from refrigerant lines and HVAC systems, ensuring optimal system performance and efficiency.

These are just a few examples of industries that commonly rely on vacuum pump technology. The versatility and wide-ranging applications of vacuum pumps make them indispensable tools across numerous sectors, enabling precise control over vacuum conditions, efficient manufacturing processes, and scientific investigations.

editor by Dream 2024-05-10

China Professional Industrial Vacuum Pump High Pressure Air Blower Xgb Vortex Gas Air Pump CNC Machine Compressor Vacuum Pump for CNC Router Tableno Reviews Yet vacuum pump ac system

Product Description

Product Description

Customized support OEM

Place of Origin China

Power Source Electric

Structure Vacuum Pump

Warranty 1 year

Brand Name lq

Model Number customized

Horsepower /

Outlet Size /

Power /

motor /

Product name air pump

Voltage 380V

Warranty 1year

Material aluminium alloy

Type air

Keywords pump

MOQ 1set

frequency 50/60 Hz

phase 3 phase

Certification ce

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Product Name: | Air Pump |

|---|---|

| Voltage: | 380V |

| Warranty: | 1year |

| Material: | Aluminium Alloy |

| Type: | Air |

| Keywords: | Pump |

| Customization: |

Available

|

|

|---|

How to install a vacuum pump

A vacuum pump creates a relative vacuum within a sealed volume by drawing gas molecules from the sealed volume. Vacuum pumps can be used in a variety of industrial applications. They also offer various lubrication options. If you are considering purchasing, please understand its functions and features before purchasing.

How it works

The working principle of a vacuum pump is called gas transfer. The principle can be further divided into two basic categories: positive displacement and momentum transfer. At high pressure and moderate vacuum, gas molecules collide and move and create a viscous flow. At higher vacuum levels, gas molecules separate to create molecular or transitional flows.

Another principle of vacuum pumps is fluid-tightness. There are two main types of seals: rotary seals and screw seals. Rotary seals prevent liquid leakage, while screw seals only allow liquids to flow out at higher pressures. Some pumps may not use the third seal.

The flow rate of the vacuum pump determines the machine’s ability to pump a certain amount of material. A higher pumping speed will shorten the drain time. Therefore, the mass flow of the vacuum pump must be carefully considered. The speed and type of vacuum must also be considered.

The working principle of a vacuum pump is to push gas molecules from a high-pressure state to a low-pressure state. This creates a partial vacuum. There are many different types of vacuum pumps, each with different functions. Some are mechanical, some are chemical. In either case, their function is the same: to create a partial or complete vacuum. Vacuum pumps use a variety of technologies and are sized according to the application. Proper sizing is critical for optimum efficiency.

Gas transfer pumps use the same principles as vacuum pumps but use different technology. One of the earliest examples is the Archimedes spiral. Its structure consists of a single screw inside a hollow cylinder. More modern designs use double or triple screws. The rotation of the screw causes gas molecules to be trapped in the cavity between the screw and the housing. The fluid is then discharged at slightly above atmospheric pressure. This difference is called the compression ratio.

Another type of vacuum pump is a diffusion pump. Its main use is industrial vacuum processing. It is used in applications such as mass spectrometry, nanotechnology and analytical instrumentation. These pumps are generally inexpensive to purchase and operate.

Apply

Vacuum pumps are essential for many scientific and industrial processes. They are used in the production of vacuum tubes, CRTs, lamps and semiconductor processing. They can also be used to support mechanical equipment. For example, they can be mounted on the engine of a motor vehicle. Likewise, they can be used to power hydraulic components of aircraft. Among other uses, the vacuum pump helps calibrate the gyroscope.

Vacuum pumps are widely used in the pharmaceutical industry and are one of the largest users of this technology. They help deal with hazardous materials and eliminate waste quickly. They are also used in power jets, dump fuel tanks and rear doors, among others. However, they are sensitive to contamination and should only be used in environments where leaks can be prevented. Therefore, choosing the right fluid for the application is very important.

The most popular type of vacuum pump is the rotary vane pump. These pumps are known for their high pumping speed and low pressure. Their efficient pumping capacity allows them to reach pressures below 10-6 bar. Additionally, they are usually oil-sealed and have excellent vacuuming capabilities.

Vacuum pumps are often used to remove air from closed systems. They create a vacuum by reducing the density of the air in the compressed space. This is done by using the mechanical force energy generated by the rotating shaft. When the pump is under pressure, it converts this energy into pneumatic power. When the pressure is different, the energy produced depends on the volume of the gas and the pressure difference between the inner and outer atmospheres.

Vacuum pumps are also used in the manufacture of solar cells. They are used in the manufacture of solar cells, including ingot casting processes as well as cell and module processes. The design of the vacuum system plays an important role in reducing the cost of the process, thus making it profitable. Due to their low maintenance costs, they are an invaluable tool for making solar cells.

Vacuum pumps are widely used in many applications. In addition to industrial and research uses, they are also used in water remediation.

Oil Lubrication Option

Vacuum pumps are available in a variety of oil lubrication options. Choosing the right lubricant can help protect your vacuum pump and maximize its performance. Different base oils may contain different additives, such as antioxidants, and some contain additional additives for specific purposes. You should choose an oil with the right concentration of these additives for optimal lubrication of your vacuum pump.

Vacuum pumps are usually lubricated with paraffinic mineral oil. However, this type of lubricant evaporates as the temperature increases. To minimize evaporative losses, choose a lubricant with low vapor pressure. Also, you should choose lubricants that are resistant to extreme temperatures. Extreme temperatures can put extra stress on the oil and can even significantly shorten the life of the oil.

In terms of viscosity, synthetic oils are the best choice for vacuum pumps. These types of oils are designed to resist gas dissolution and are more resistant to corrosion. Therefore, synthetic oils are ideal for handling aggressive substances. Whether or not your pump needs lubrication, choosing a quality product is important.

The vacuum pump oil should be changed periodically according to the manufacturer’s recommendations. If you use a filter, you should also change the oil as soon as the filter reaches the end of its life. Unplanned oil changes will eventually cause the vacuum pump to not reach its maximum vacuum capacity.

You can buy vacuum pump oil from vacuum pump manufacturers or other suppliers. These options are available in a variety of sizes, and labels can be customized. The oil should be designed for the pump. However, you should check the manufacturer’s recommendations to avoid buying the wrong type.

If you choose to use a synthetic oil, it is important to use a good quality oil. It helps the pump work more efficiently and prolong its life.

Install

After choosing a suitable location, the next step is to install the pump. First, place the pump on a flat surface. Then, screw the pump onto the motor body above the check valve. Make sure the accessories are wrapped with sealing tape and secured with screws. The direction of gas inflow and outflow is indicated by arrows on the pump. The direction of rotation around the pump is also shown.

During commissioning, check the operation of each part of the pump. If the pump is equipped with a pipe connection, the pipe should be the same size and shape as the pump flange. Also, make sure that the piping does not cause any pressure drop. In addition, the first three weeks of operation require the installation of protective nets at the suction ports.

When selecting a pump, consider the back pressure of the system. Too much back pressure will affect the capacity of the vacuum pump. Also, check the temperature of the seal. If the temperature is too high, the seal may be damaged. It could also be due to a partially closed valve in the recirculation line or a clogged filter. Circulation pumps and heat exchangers should also be checked for fouling.

The vacuum pump is usually installed in the chassis area of the car. They can be mounted next to the engine or on a lower support frame. They are usually fastened to the bracket using suitable shock absorbers and isolating elements. However, before installing the vacuum pump, be sure to check the vacuum pump’s wiring harness before connecting it to the vehicle.

In many experimental setups, a vacuum pump is essential. However, improperly installed vacuum pumps can expose users to harmful vapors and chemicals. Appropriate plugs and belt guards should be installed to prevent any accidental chemical exposure. It is also important to install a fume hood for the pump.

In most cases, vacuum pumps come with installation manuals and instructions. Some manufacturers even offer start-up assistance if needed.

editor by Dream 2024-05-09

China supplier DC Mini Air Pump 3/6/9/12V Micro Diaphragm Vacuum Pump for Blackhead Instrument with high quality

Product Description

Product Description

Features

1. Life: Expected life span is >=30,000 Times(on 10s/off 5s).

2. Low noise: ≤60dB, far from 30cm distance.

3. Working conditions: Applying to indoor and outdoor under temperature 60 deg C.

4. Have suction function. can run continuously.

5. It can be powered directly by a Solar panel, DC electric source, or battery.

Dimensional drawing and working curve diagram

Widely used for Home appliances,medical,blackhead meters, breast pumps, vacuum packaging machines, massage

machines, foam hand sanitizers, teeth flushers and other products; household appliances, medical treatment, beauty,

massagers,adult products,Sphygmomanometers, Essential oil machines,Booster technology etc. Industries

We supply Full Customization Service, please contact us for the details.

Certifications

Our Advantages

FAQ

Do you accept OEM/ODM Service?

Yes, we have been the professional OEM/ODM supplier for many years.

What’s your main products?

Brushless dc water pump, drinking pump, solar pump, submersible pump, centrifugal pump, diaphragm pump, booster

pump, etc… for many years we develop the products with our client together, also customize the products they want.

How can I choose the pump?

We can study together for the using purpose, specification in the working condition, then we will suggest you the

most suitable 1 from our products range.

What’s your product MOQ?

We accept sample order, the MOQ can be negotiated.

How long is your delivery time?

Sample order within 1 week. Bulk order within 25 days. If the pumps in stock, within2 days.

How long is your warranty of pump?

Warranty is 1 year, can be repaired free of charge

What’s the payment method?

By Trade Assurance, Paypal, T/T, L/C, Western Union, etc…

What certificates have your pumps passed?

All our products have passed CE, RoHs, Reach. Parts of pumps met UL.

How do you ship the goods?

Shipping by express (sample order) and by air or by sea (bulk order). Pls contact us before order because the freight

fee base on quantity

What’s your port of loading?

HangZhou port, HangZhou port, HangZhou port, for other we can communicate it.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, CE |

|---|---|

| Voltage: | Low Pressure |

| Material: | ABS |

| Trademark: | Desun |

| Origin: | China, Dongguan |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|