Product Description

We are looking for the agents from all over the world.

If you want to represent our products, welcome to contact me.

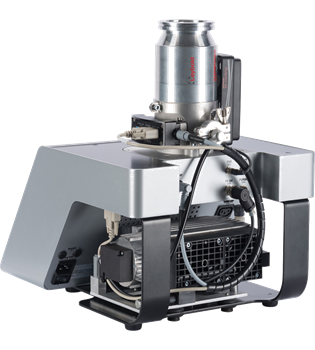

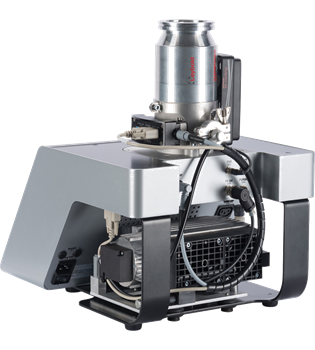

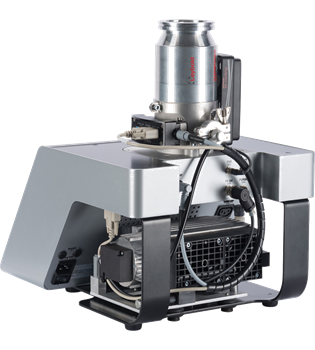

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.Dry Oil-Free Air Cooling Screw Vacuum Pump ,This is an advanced and widely used vacuum pump at present, It is 1 of the best-selling products of our company.

It adopts explosion-proof motor with high configuration, It has the characteristics of low noise, no oil and pollution, clean and high vacuum, simple and convenient use, operation and maintenance, Widely used in many industries, For example, oil and gas recovery, vacuum coating, biomedicine, food processing, single crystal furnace, vacuum forming, vacuum melting, electronic photovoltaic, semiconductor synthesis and many other industries are used.

The dry oil-free screw vacuum pump produced by our company is divided into air cooling and water cooling according to the extraction rate, and there are many models for you to choose.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

Vacuum pumps are used in oiling machines

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

New plant plHangZhou

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

High precision machining equipment

The company cooperates with many scientific research institutions and universities, such as ZheJiang University, China University of petroleum, ZheJiang Institute of mechanical design, etc.with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents.Our technology is leading, the product quality is stable, the product has a good reputation in China’s domestic market, is sold all over the country, and is exported to Europe, America, Africa, the Middle East and Southeast Asia,We adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

Product quality wins consumer cooperation

In shipment

ISO 9001

High tech enterprise certificate

Welcome to send your needs, we will provide you with the best service,

provide the greatest help!!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | One Year |

|---|---|

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used for Vacuum Packaging?

Yes, vacuum pumps can be used for vacuum packaging. Here’s a detailed explanation:

Vacuum packaging is a method used to remove air from a package or container, creating a vacuum environment. This process helps to extend the shelf life of perishable products, prevent spoilage, and maintain product freshness. Vacuum pumps play a crucial role in achieving the desired vacuum level for effective packaging.

When it comes to vacuum packaging, there are primarily two types of vacuum pumps commonly used:

1. Single-Stage Vacuum Pumps: Single-stage vacuum pumps are commonly used for vacuum packaging applications. These pumps use a single rotating vane or piston to create a vacuum. They can achieve moderate vacuum levels suitable for most packaging requirements. Single-stage pumps are relatively simple in design, compact, and cost-effective.

2. Rotary Vane Vacuum Pumps: Rotary vane vacuum pumps are another popular choice for vacuum packaging. These pumps utilize multiple vanes mounted on a rotor to create a vacuum. They offer higher vacuum levels compared to single-stage pumps, making them suitable for applications that require deeper levels of vacuum. Rotary vane pumps are known for their reliability, consistent performance, and durability.

When using vacuum pumps for vacuum packaging, the following steps are typically involved:

1. Preparation: Ensure that the packaging material, such as vacuum bags or containers, is suitable for vacuum packaging and can withstand the vacuum pressure without leakage. Place the product to be packaged inside the appropriate packaging material.

2. Sealing: Properly seal the packaging material, either by heat sealing or using specialized vacuum sealing equipment. This ensures an airtight enclosure for the product.

3. Vacuum Pump Operation: Connect the vacuum pump to the packaging equipment or directly to the packaging material. Start the vacuum pump to initiate the vacuuming process. The pump will remove the air from the packaging, creating a vacuum environment.

4. Vacuum Level Control: Monitor the vacuum level during the packaging process using pressure gauges or vacuum sensors. Depending on the specific packaging requirements, adjust the vacuum level accordingly. The goal is to achieve the desired vacuum level suitable for the product being packaged.

5. Sealing and Closure: Once the desired vacuum level is reached, seal the packaging material completely to maintain the vacuum environment. This can be done by heat sealing the packaging material or using specialized sealing mechanisms designed for vacuum packaging.

6. Product Labeling and Storage: After sealing, label the packaged product as necessary and store it appropriately, considering factors such as temperature, humidity, and light exposure, to maximize product shelf life.

It’s important to note that the specific vacuum level required for vacuum packaging may vary depending on the product being packaged. Some products may require a partial vacuum, while others may require a more stringent vacuum level. The choice of vacuum pump and the control mechanisms employed will depend on the specific vacuum packaging requirements.

Vacuum pumps are widely used in various industries for vacuum packaging applications, including food and beverage, pharmaceuticals, electronics, and more. They provide an efficient and reliable means of creating a vacuum environment, helping to preserve product quality and extend shelf life.

What Is the Difference Between Dry and Wet Vacuum Pumps?

Dry and wet vacuum pumps are two distinct types of pumps that differ in their operating principles and applications. Here’s a detailed explanation of the differences between them:

Dry Vacuum Pumps:

Dry vacuum pumps operate without the use of any lubricating fluid or sealing water in the pumping chamber. They rely on non-contact mechanisms to create a vacuum. Some common types of dry vacuum pumps include:

1. Rotary Vane Pumps: Rotary vane pumps consist of a rotor with vanes that slide in and out of slots in the rotor. The rotation of the rotor creates chambers that expand and contract, allowing the gas to be pumped. The vanes and the housing are designed to create a seal, preventing gas from flowing back into the pump. Rotary vane pumps are commonly used in laboratories, medical applications, and industrial processes where a medium vacuum level is required.

2. Dry Screw Pumps: Dry screw pumps use two or more intermeshing screws to compress and transport gas. As the screws rotate, the gas is trapped between the threads and transported from the suction side to the discharge side. Dry screw pumps are known for their high pumping speeds, low noise levels, and ability to handle various gases. They are used in applications such as semiconductor manufacturing, chemical processing, and vacuum distillation.

3. Claw Pumps: Claw pumps use two rotors with claw-shaped lobes that rotate in opposite directions. The rotation creates a series of expanding and contracting chambers, enabling gas capture and pumping. Claw pumps are known for their oil-free operation, high pumping speeds, and suitability for handling dry and clean gases. They are commonly used in applications such as automotive manufacturing, food packaging, and environmental technology.

Wet Vacuum Pumps:

Wet vacuum pumps, also known as liquid ring pumps, operate by using a liquid, typically water, to create a seal and generate a vacuum. The liquid ring serves as both the sealing medium and the working fluid. Wet vacuum pumps are commonly used in applications where a higher level of vacuum is required or when handling corrosive gases. Some key features of wet vacuum pumps include:

1. Liquid Ring Pumps: Liquid ring pumps feature an impeller with blades that rotate eccentrically within a cylindrical casing. As the impeller rotates, the liquid forms a ring against the casing due to centrifugal force. The liquid ring creates a seal, and as the impeller spins, the volume of the gas chamber decreases, leading to the compression and discharge of gas. Liquid ring pumps are known for their ability to handle wet and corrosive gases, making them suitable for applications such as chemical processing, oil refining, and wastewater treatment.

2. Water Jet Pumps: Water jet pumps utilize a jet of high-velocity water to create a vacuum. The water jet entrains gases, and the mixture is then separated in a venturi section, where the water is recirculated, and the gases are discharged. Water jet pumps are commonly used in laboratories and applications where a moderate vacuum level is required.

The main differences between dry and wet vacuum pumps can be summarized as follows:

1. Operating Principle: Dry vacuum pumps operate without the need for any sealing fluid, while wet vacuum pumps utilize a liquid ring or water as a sealing and working medium.

2. Lubrication: Dry vacuum pumps do not require lubrication since there is no contact between moving parts, whereas wet vacuum pumps require the presence of a liquid for sealing and lubrication.

3. Applications: Dry vacuum pumps are suitable for applications where a medium vacuum level is required, and oil-free operation is desired. They are commonly used in laboratories, medical settings, and various industrial processes. Wet vacuum pumps, on the other hand, are used when a higher vacuum level is needed or when handling corrosive gases. They find applications in chemical processing, oil refining, and wastewater treatment, among others.

It’s important to note that the selection of a vacuum pump depends on specific requirements such as desired vacuum level, gas compatibility, operating conditions, and the nature of the application.

In summary, the primary distinction between dry and wet vacuum pumps lies in their operating principles, lubrication requirements, and applications. Dry vacuum pumps operate without any lubricating fluid, while wet vacuum pumps rely on a liquid ring or water for sealing and lubrication. The choice between dry and wet vacuum pumps depends on the specific needs of the application and the desired vacuum level.

Can Vacuum Pumps Be Used in Laboratories?

Yes, vacuum pumps are extensively used in laboratories for a wide range of applications. Here’s a detailed explanation:

Vacuum pumps are essential tools in laboratory settings as they enable scientists and researchers to create and control vacuum or low-pressure environments. These controlled conditions are crucial for various scientific processes and experiments. Here are some key reasons why vacuum pumps are used in laboratories:

1. Evaporation and Distillation: Vacuum pumps are frequently used in laboratory evaporation and distillation processes. By creating a vacuum, they lower the boiling point of liquids, allowing for gentler and more controlled evaporation. This is particularly useful for heat-sensitive substances or when precise control over the evaporation process is required.

2. Filtration: Vacuum filtration is a common technique in laboratories for separating solids from liquids or gases. Vacuum pumps create suction, which helps draw the liquid or gas through the filter, leaving the solid particles behind. This method is widely used in processes such as sample preparation, microbiology, and analytical chemistry.

3. Freeze Drying: Vacuum pumps play a crucial role in freeze drying or lyophilization processes. Freeze drying involves removing moisture from a substance while it is in a frozen state, preserving its structure and properties. Vacuum pumps facilitate the sublimation of frozen water directly into vapor, resulting in the removal of moisture under low-pressure conditions.

4. Vacuum Ovens and Chambers: Vacuum pumps are used in conjunction with vacuum ovens and chambers to create controlled low-pressure environments for various applications. Vacuum ovens are used for drying heat-sensitive materials, removing solvents, or conducting reactions under reduced pressure. Vacuum chambers are utilized for testing components under simulated space or high-altitude conditions, degassing materials, or studying vacuum-related phenomena.

5. Analytical Instruments: Many laboratory analytical instruments rely on vacuum pumps to function properly. For example, mass spectrometers, electron microscopes, surface analysis equipment, and other analytical instruments often require vacuum conditions to maintain sample integrity and achieve accurate results.

6. Chemistry and Material Science: Vacuum pumps are employed in numerous chemical and material science experiments. They are used for degassing samples, creating controlled atmospheres, conducting reactions under reduced pressure, or studying gas-phase reactions. Vacuum pumps are also used in thin film deposition techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD).

7. Vacuum Systems for Experiments: In scientific research, vacuum systems are often designed and constructed for specific experiments or applications. These systems can include multiple vacuum pumps, valves, and chambers to create specialized vacuum environments tailored to the requirements of the experiment.

Overall, vacuum pumps are versatile tools that find extensive use in laboratories across various scientific disciplines. They enable researchers to control and manipulate vacuum or low-pressure conditions, facilitating a wide range of processes, experiments, and analyses. The choice of vacuum pump depends on factors such as required vacuum level, flow rate, chemical compatibility, and specific application needs.

editor by Dream 2024-05-15

China Hot selling CHINAMFG Laboratory Equipment 20 L/Min Single Head Diaphragm Vacuum Pump vacuum pump oil near me

Product Description

GM-0.33A New Product Single Head Diaphragm Vacuum Pump

GM0.33A diaphragm vacuum pump has features of more advanced design, higher efficiency, longer operating life.It is an all new product engaging in the new and high technology.It is mainly used in medicinal products analysis,tenuously chemical engineering, biochemical pharmacy,food examination, investigating and solving criminal case,etc. It is an ideal product used with the highaccuracy chromatogram apparatus, HPLC solvent filter apparatus, and it is the essential equipment in the laboratory.

The body of GM-0.33A diaphragm vacuum pump is made of aluminum alloy through die casting.

It is antiseptic, sprayed, agile and beautiful. It has the features of higher antisepsis, wider working range. It can meet requirements of all kinds of working environments.

| Speed of Evacuation | 20 L/Min | Pump Head | 1 |

| Ultimate Pressure | ≥0.08MPa | Voltage Rating | 230VAC, 50Hz |

| Vacuum | 200mbar | Noise Level(dB) | <50 |

| Dimensions (L X B X H) | 215×120×235mm | Temp of the body | <55 ºC |

| Motor Power(w) | 160 | Weight (Kg) | 7.5 |

| Inlet (mm) | φ6 | Diaphragm | NBR |

| Outlet (mm) | Silencer | Valves | NBR |

| Working Temp(ºC) | 7-40 |

BIOBASE GROUP CHINA

Established in 1999

Leading professional manufacturer of laboratory and medical products with high quality and competitive price,

Specializing in:

*air protection products

*cold chain products

*analytical instruments

*most of lab and medical products

*laboratory furniture,laboratory and clean room construction

1200employees in China and abroad offices.

Our mission is to enable our customers to make the world healthier,cleanerand safer.

BIOBASE group invests in science and technology researches,aims to keep improving products

performance and quality as well as develops new products to meet customers’wide requirement.

We satisfy our customers by offering comprehensive support,purchase convenience and we are ready to

serve more and more BIOBASE users.

BIOBASE group,serving global distributors and its loyal end users,is becoming one of the most

important scientific services supplier.

Website: biobase biobase

BIOBASE Group is your best choice for Partner.

Contact Us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Support |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil Free |

| Structure: | Reciprocating Vacuum Pump |

| Exhauster Method: | Positive Displacement Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

What safety features are typically integrated into diaphragm vacuum pump systems?

Diaphragm vacuum pump systems typically incorporate various safety features to ensure safe operation and protect both the users and the equipment. Here’s a detailed explanation:

1. Overpressure Protection: Diaphragm vacuum pump systems often include overpressure protection mechanisms to prevent excessive pressure buildup. These mechanisms can be in the form of pressure relief valves or pressure sensors that automatically shut off the pump or release excess pressure if it exceeds the predefined limits. Overpressure protection safeguards the system from potential damage and reduces the risk of accidents or equipment failure.

2. Thermal Protection: Thermal protection features are designed to prevent the pump from overheating. Diaphragm pumps can generate heat during operation, especially in continuous or intensive use. Thermal protection mechanisms, such as thermal switches or temperature sensors, monitor the pump’s temperature and automatically shut it down or activate cooling systems if the temperature exceeds safe limits. This helps prevent damage to the pump and reduces the risk of fire or other safety hazards.

3. Leak Detection: Diaphragm vacuum pump systems may incorporate leak detection mechanisms to alert users in case of any air or gas leakage. These mechanisms can include pressure sensors or flow sensors that monitor the system’s integrity. If a leak is detected, visual or audible alarms may be triggered, indicating the need for immediate attention and repair to maintain the system’s efficiency and prevent the release of potentially harmful substances into the environment.

4. Electrical Safety: Diaphragm pump systems have electrical safety features to protect against electrical hazards. This includes measures such as ground fault circuit interrupters (GFCI) or residual current devices (RCD) that detect and interrupt electrical faults, preventing electric shocks or short circuits. Proper grounding and insulation of electrical components are also important safety considerations in diaphragm pump systems.

5. Emergency Stop: Many diaphragm pump systems are equipped with an emergency stop button or switch that allows users to quickly shut down the pump in case of an emergency or hazardous situation. The emergency stop feature provides a convenient and immediate means to halt pump operation, ensuring the safety of the users and preventing further risks or damages.

6. System Monitoring and Alarms: Advanced diaphragm pump systems may incorporate monitoring features that continuously assess the system’s performance and provide real-time feedback. This can include monitoring parameters such as vacuum levels, temperature, pressure, or flow rates. Alarms or visual indicators are often integrated to alert users in case of deviations from normal operating conditions, enabling prompt corrective actions and preventing potential safety issues.

It’s important to note that the specific safety features integrated into diaphragm vacuum pump systems may vary depending on the manufacturer, model, and intended application. Users should carefully review the product documentation and follow the manufacturer’s instructions regarding safety precautions, installation requirements, and maintenance procedures to ensure safe and proper use of the equipment.

In summary, diaphragm vacuum pump systems typically incorporate safety features such as overpressure protection, thermal protection, leak detection, electrical safety measures, emergency stop functionalities, and system monitoring with alarms. These safety features aim to protect users, prevent equipment damage, and ensure the safe and reliable operation of the diaphragm pump system.

What is the noise level produced by diaphragm vacuum pumps during operation?

The noise level produced by diaphragm vacuum pumps during operation can vary depending on factors such as pump design, size, and operating conditions. Here’s a detailed explanation:

Diaphragm vacuum pumps are generally known for their relatively quiet operation compared to other types of vacuum pumps. The noise level produced by diaphragm pumps is typically lower than that of oil-sealed rotary vane pumps or piston pumps.

The noise level is influenced by various factors, including:

– Pump Design: The design of the diaphragm pump can affect the noise level. Some pumps are specifically engineered to minimize noise by incorporating features such as noise-reducing materials, vibration dampening mechanisms, or sound insulation.

– Pump Size and Power: Larger diaphragm pumps may generate more noise compared to smaller ones due to increased air displacement and higher power requirements. It’s important to consider the specific size and power rating of the pump when evaluating its noise level.

– Operating Conditions: The noise level can also be influenced by the operating conditions of the diaphragm pump. Factors such as speed, temperature, and the presence of vibrations or resonances in the system can impact the overall noise output.

While diaphragm vacuum pumps are generally considered to have low noise levels, it’s important to note that individual pump models may have different noise specifications. Manufacturers often provide noise level data in the pump’s technical documentation, which can help in selecting a pump that meets specific noise requirements.

Additionally, it’s worth considering noise reduction measures such as using vibration isolation pads, enclosing the pump in a soundproof housing, or employing remote mounting techniques to further minimize any noise generated by the pump.

In summary, diaphragm vacuum pumps are known for their relatively quiet operation compared to other types of vacuum pumps. However, the actual noise level produced can vary depending on factors such as pump design, size, and operating conditions. Consulting the manufacturer’s specifications and implementing noise reduction measures can help ensure a suitable noise level for the intended application.

What is a diaphragm vacuum pump, and how does it operate?

A diaphragm vacuum pump is a type of positive displacement pump used to create vacuum or low-pressure conditions in various applications. Here’s a detailed explanation of its operation:

Overview:

A diaphragm vacuum pump consists of a flexible diaphragm that moves back and forth within a chamber. As the diaphragm flexes, it creates changes in the volume of the chamber, resulting in the suction and expulsion of gas. The diaphragm is typically made of a durable, chemically resistant material such as rubber or elastomer.

Operation:

The operation of a diaphragm vacuum pump typically involves the following steps:

1. Suction Phase: The diaphragm starts in a neutral position. When the pump is powered on, the diaphragm is pulled downward by the negative pressure within the chamber. This expansion of the chamber volume creates suction, drawing gas or vapor into the pump through the inlet valve or port.

2. Compression Phase: Once the diaphragm reaches its maximum downward position, the inlet valve closes to prevent backflow. The diaphragm then starts to move upward, reducing the volume of the chamber. This compression action causes the gas to be expelled through the outlet valve or port.

3. Exhaust Phase: As the diaphragm continues to move upward, the outlet valve closes, and the compressed gas is discharged from the pump. The diaphragm returns to its neutral position, ready for the next suction phase.

Features and Advantages:

Diaphragm vacuum pumps offer several features and advantages that make them suitable for various applications:

– No Contamination: Diaphragm pumps are designed to be oil-free and have a sealed pumping chamber. This eliminates the risk of oil contamination of the pumped gas or vapor, making them suitable for applications requiring clean and uncontaminated vacuum conditions, such as laboratory work or medical applications.

– Chemical Resistance: The diaphragm is typically made of chemically resistant materials, allowing the pump to handle corrosive or reactive gases without degradation or contamination.

– Gentle Operation: The pumping action of diaphragm pumps is gentle and pulsation-free, making them suitable for applications that require precise control or sensitive handling of gases or delicate samples.

– Quiet Operation: Diaphragm pumps are known for their quiet operation, reducing noise pollution in the working environment.

– Self-Priming: Diaphragm pumps are generally self-priming, meaning they can start and maintain their pumping action without the need for external priming or additional equipment.

– Compact and Portable: Diaphragm pumps are often compact and lightweight, allowing for easy installation and portability. They can be used as standalone units or integrated into larger systems.

Applications:

Diaphragm vacuum pumps find applications in various industries and fields, including:

– Laboratory research and analysis

– Medical and healthcare

– Environmental monitoring and analysis

– Vacuum filtration

– Vacuum drying and degassing

– Automotive and manufacturing processes

– Semiconductor and electronics manufacturing

It is important to note that the specific design and operation of diaphragm vacuum pumps may vary across different manufacturers and models. Consulting the manufacturer’s specifications and guidelines is recommended for detailed information on the operation, performance, and suitability of a particular diaphragm pump for a given application.

By utilizing the flexible diaphragm’s movement to create suction and compression, diaphragm vacuum pumps offer reliable and efficient vacuum generation for a wide range of applications.

editor by Dream 2024-05-14

China wholesaler API 11ax 25-150rhb Oil Sucker Rod Pump vacuum pump and compressor

Product Description

API 11AX 25-150RHB oil sucker rod pump

Product Description

This pump barrel uses a suspension structure, thus it improves the load bearing structure and makes the pump work in the deep well. The setting depth of pump could be 500-1500 CHINAMFG deep. This pump has the following characteristics: to prevent bending, the pump uses the gap bridge structure, the barrel is suspended in the outer section and does not bear any pressure thus, not easy to bend. The space between the plunger and barrel reduces eccentric wear thus, extended the service life and guarantee improved pump efficiency. To prevent loss, the related eccentric distance ε=0. This eccentric distance between barrel and plunger reduce pump loss. This pump is suitable for the deep wells, which where 1 needs to hang more tail pipes.

Oil and Gas Production Subsurface Sucker Rod Pump(Rod Type)

| Specification | Nominal Pump Bore (in) | Plunger Length(ft) | Max.O.D.(mm) | Rod(in) | Tubing(in) | Pump Constant (m3/d) | Stroke (m) |

| 20-112RHBC | 1.12 | 4~6 | 46.7 | 3/4 | 2 3/8 | 0.92 | ≤7.5 |

| 20-112RHBM | 44.7 | ||||||

| 20-125RHBC | 1.25 | 47.5 | 3/4 | 2 3/8 | 1.14 | ||

| 20-125RHBM | 44.7 | ||||||

| 25-150RHBC | 1.5 | 59.5 | 3/4 | 2 7/8 | 1.64 | ||

| 25-150RHBM | 55.6 | ||||||

| 25-175RHBC | 1.75 | 59.5 | 3/4 | 2 7/8 | 2.24 | ||

| 25-175RHBM | 55.6 | ||||||

| 30-225RHBC | 2.25 | 72.1 | 3/4 | 3 1/2 | 3.69 | ||

| 30-225RHBM | 71.7 |

Oil and Gas Production Subsurface Sucker Rod Pump (Tubing Type)

| Pump designation | Pump Bore(in) | Length of Plunger (mm) | Range of Stroke (mm) | Pump Constant (m3/d) | Size of matched tubing (in) | Size of connecting Sucker Rod(mm) | Length of extension Coupling |

| 25-125 | 1.25 | 600-1200 | 600-1200 | 1.14 | 2-1/2 2-7/8 | 16 | 300-900 |

| 25-150 | 1.5 | 1.642 | 2-1/2 2-7/8 | 16 | |||

| 25-175 | 1.75 | 2.235 | 2-1/2 2-7/8 | 16 | |||

| 20-175 | |||||||

| 25-225 | 2.25 | 3.694 | 2-7/8 | 19 | |||

| 25-275 | 2.75 | 5.518 | 2-7/8 | 22 | |||

| 30-275 | 2.75 | 5.518 | 3-1/2 | 22 | |||

| 30-325 | 3.25 | 7.707 | 3-1/2 | 22 | |||

| 30-375 | 3.75 | 10.261 | 3-1/2 | 25 | |||

| 40-375 | 3.75 | 10.261 | 4 | 25 |

Company Profile

FAQ

1.Are you a factory?

Yes,we have our own factory for manufacturing and we have the long history in this field as the China top brand.

2.Can you provide free sample?

Yes, we can provide samples in our stock for free, customer just need to bear the shipping fee.

3. Hhow about the quality guarantee ?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

4.what can you buy from us?

OCTG / Pumping Unit / Sucker Rod Pump / Wellhead and Christmas Tree / Casing and Coupling /Pup joint/Crossover/Centralizer

5. What is your advantages beyong other suppliers?

1).Complete categories & Reasonable price

2).Fast delivery & Quality guarantee

3).Supplier of china famous oil field and lots of US oil field etc.

4).20+ years professional manufacture major on oil equipment

6. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,Express Delivery;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Cash,Escrow;

Language Spoken:English,Chinese,Spanish

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Techinical Support |

|---|---|

| Warranty: | 1 Year |

| Manufacturing Process: | Casting |

| Surface Treatment: | Polishing |

| Operation Pressure: | Vacuum |

| Material: | Cast Steel |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used for Vacuum Furnaces?

Yes, vacuum pumps can be used for vacuum furnaces. Here’s a detailed explanation:

Vacuum furnaces are specialized heating systems used in various industries for heat treatment processes that require controlled environments with low or no atmospheric pressure. Vacuum pumps play a crucial role in creating and maintaining the vacuum conditions necessary for the operation of vacuum furnaces.

Here are some key points regarding the use of vacuum pumps in vacuum furnaces:

1. Vacuum Creation: Vacuum pumps are used to evacuate the furnace chamber, creating a low-pressure or near-vacuum environment. This is essential for the heat treatment processes carried out in the furnace, as it helps eliminate oxygen and other reactive gases, preventing oxidation or unwanted chemical reactions with the heated materials.

2. Pressure Control: Vacuum pumps provide the means to control and maintain the desired pressure levels within the furnace chamber during the heat treatment process. Precise pressure control is necessary to achieve the desired metallurgical and material property changes during processes such as annealing, brazing, sintering, and hardening.

3. Contamination Prevention: By removing gases and impurities from the furnace chamber, vacuum pumps help prevent contamination of the heated materials. This is particularly important in applications where cleanliness and purity of the processed materials are critical, such as in the aerospace, automotive, and medical industries.

4. Rapid Cooling: Some vacuum furnace systems incorporate rapid cooling capabilities, known as quenching. Vacuum pumps assist in facilitating the rapid cooling process by removing the heat generated during quenching, ensuring efficient cooling and minimizing distortion or other unwanted effects on the treated materials.

5. Process Flexibility: Vacuum pumps provide flexibility in the type of heat treatment processes that can be performed in vacuum furnaces. Different heat treatment techniques, such as vacuum annealing, vacuum brazing, or vacuum carburizing, require specific pressure levels and atmospheric conditions that can be achieved and maintained with the use of vacuum pumps.

6. Vacuum Pump Types: Different types of vacuum pumps can be used in vacuum furnaces, depending on the specific requirements of the heat treatment process. Commonly used vacuum pump technologies include oil-sealed rotary vane pumps, dry screw pumps, diffusion pumps, and cryogenic pumps. The choice of vacuum pump depends on factors such as required vacuum level, pumping speed, reliability, and compatibility with the process gases.

7. Maintenance and Monitoring: Proper maintenance and monitoring of vacuum pumps are essential to ensure their optimal performance and reliability. Regular inspections, lubrication, and replacement of consumables (such as oil or filters) are necessary to maintain the efficiency and longevity of the vacuum pump system.

8. Safety Considerations: Operating vacuum furnaces with vacuum pumps requires adherence to safety protocols. This includes proper handling of potentially hazardous gases or chemicals used in the heat treatment processes, as well as following safety guidelines for operating and maintaining the vacuum pump system.

Overall, vacuum pumps are integral components of vacuum furnaces, enabling the creation and maintenance of the required vacuum conditions for precise and controlled heat treatment processes. They contribute to the quality, consistency, and efficiency of the heat treatment operations performed in vacuum furnaces across a wide range of industries.

Can Vacuum Pumps Be Used for Chemical Distillation?

Yes, vacuum pumps are commonly used in chemical distillation processes. Here’s a detailed explanation:

Chemical distillation is a technique used to separate or purify components of a mixture based on their different boiling points. The process involves heating the mixture to evaporate the desired component and then condensing the vapor to collect the purified substance. Vacuum pumps play a crucial role in chemical distillation by creating a reduced pressure environment, which lowers the boiling points of the components and enables distillation at lower temperatures.

Here are some key aspects of using vacuum pumps in chemical distillation:

1. Reduced Pressure: By creating a vacuum or low-pressure environment in the distillation apparatus, vacuum pumps lower the pressure inside the system. This reduction in pressure lowers the boiling points of the components, allowing distillation to occur at temperatures lower than their normal boiling points. This is particularly useful for heat-sensitive or high-boiling-point compounds that would decompose or become thermally degraded at higher temperatures.

2. Increased Boiling Point Separation: Vacuum distillation increases the separation between the boiling points of the components, making it easier to achieve a higher degree of purification. In regular atmospheric distillation, the boiling points of some components may overlap, leading to less effective separation. By operating under vacuum, the boiling points of the components are further apart, improving the selectivity and efficiency of the distillation process.

3. Energy Efficiency: Vacuum distillation can be more energy-efficient compared to distillation under atmospheric conditions. The reduced pressure lowers the required temperature for distillation, resulting in reduced energy consumption and lower operating costs. This is particularly advantageous when dealing with large-scale distillation processes or when distilling heat-sensitive compounds that require careful temperature control.

4. Types of Vacuum Pumps: Different types of vacuum pumps can be used in chemical distillation depending on the specific requirements of the process. Some commonly used vacuum pump types include:

– Rotary Vane Pumps: Rotary vane pumps are widely used in chemical distillation due to their ability to achieve moderate vacuum levels and handle various gases. They work by using rotating vanes to create chambers that expand and contract, enabling the pumping of gas or vapor.

– Diaphragm Pumps: Diaphragm pumps are suitable for smaller-scale distillation processes. They use a flexible diaphragm that moves up and down to create a vacuum and compress the gas or vapor. Diaphragm pumps are often oil-free, making them suitable for applications where avoiding oil contamination is essential.

– Liquid Ring Pumps: Liquid ring pumps can handle more demanding distillation processes and corrosive gases. They rely on a rotating liquid ring to create a seal and compress the gas or vapor. Liquid ring pumps are commonly used in chemical and petrochemical industries.

– Dry Screw Pumps: Dry screw pumps are suitable for high-vacuum distillation processes. They use intermeshing screws to compress and transport gas or vapor. Dry screw pumps are known for their high pumping speeds, low noise levels, and oil-free operation.

Overall, vacuum pumps are integral to chemical distillation processes as they create the necessary reduced pressure environment that enables distillation at lower temperatures. By using vacuum pumps, it is possible to achieve better separation, improve energy efficiency, and handle heat-sensitive compounds effectively. The choice of vacuum pump depends on factors such as the required vacuum level, the scale of the distillation process, and the nature of the compounds being distilled.

How Do You Choose the Right Size Vacuum Pump for a Specific Application?

Choosing the right size vacuum pump for a specific application involves considering several factors to ensure optimal performance and efficiency. Here’s a detailed explanation:

1. Required Vacuum Level: The first consideration is the desired vacuum level for your application. Different applications have varying vacuum level requirements, ranging from low vacuum to high vacuum or even ultra-high vacuum. Determine the specific vacuum level needed, such as microns of mercury (mmHg) or pascals (Pa), and choose a vacuum pump capable of achieving and maintaining that level.

2. Pumping Speed: The pumping speed, also known as the displacement or flow rate, is the volume of gas a vacuum pump can remove from a system per unit of time. It is typically expressed in liters per second (L/s) or cubic feet per minute (CFM). Consider the required pumping speed for your application, which depends on factors such as the volume of the system, the gas load, and the desired evacuation time.

3. Gas Load and Composition: The type and composition of the gas or vapor being pumped play a significant role in selecting the right vacuum pump. Different pumps have varying capabilities and compatibilities with specific gases. Some pumps may be suitable for pumping only non-reactive gases, while others can handle corrosive gases or vapors. Consider the gas load and its potential impact on the pump’s performance and materials of construction.

4. Backing Pump Requirements: In some applications, a vacuum pump may require a backing pump to reach and maintain the desired vacuum level. A backing pump provides a rough vacuum, which is then further processed by the primary vacuum pump. Consider whether your application requires a backing pump and ensure compatibility and proper sizing between the primary pump and the backing pump.

5. System Leakage: Evaluate the potential leakage in your system. If your system has significant leakage, you may need a vacuum pump with a higher pumping speed to compensate for the continuous influx of gas. Additionally, consider the impact of leakage on the required vacuum level and the pump’s ability to maintain it.

6. Power Requirements and Operating Cost: Consider the power requirements of the vacuum pump and ensure that your facility can provide the necessary electrical supply. Additionally, assess the operating cost, including energy consumption and maintenance requirements, to choose a pump that aligns with your budget and operational considerations.

7. Size and Space Constraints: Take into account the physical size of the vacuum pump and whether it can fit within the available space in your facility. Consider factors such as pump dimensions, weight, and the need for any additional accessories or support equipment.

8. Manufacturer’s Recommendations and Expert Advice: Consult the manufacturer’s specifications, guidelines, and recommendations for selecting the right pump for your specific application. Additionally, seek expert advice from vacuum pump specialists or engineers who can provide insights based on their experience and knowledge.

By considering these factors and evaluating the specific requirements of your application, you can select the right size vacuum pump that meets the desired vacuum level, pumping speed, gas compatibility, and other essential criteria. Choosing the appropriate vacuum pump ensures efficient operation, optimal performance, and longevity for your application.

editor by Dream 2024-05-14

China manufacturer Factory Oil Wet Screw Vacuum Pump Manufacturer with Hot selling

Product Description

EXTERIOR DESIGN INTERIOR DESIGN

ZheJiang CZPT Machinery Manufacturing Co. , Ltd. is located in HangZhou, ZheJiang .CZPT is a comprehensive screw air compressor

manufacturer that engaged in R & D, design, production and sales. It has a plant of 20,000 square meters, including a large production workshop,

a comprehensive first-class exhibition hall and a testing laboratory.

CZPT has excellent mechanical engineering designers, an experienced staff team and a professional management team. The production

concept focuses on energy-saving and is committed to perfecting and improving the technological process in order to get the core technology

of super frequency energy-saving, achieving the characteristics of mute, durability, power saving and safety.

The company has 9 series of products with multiple models. Including Fixed speed air compressor, PM VSD air compressor, PM VSD

two-stage air compressor, 4-in-1 air compressor, Oil free water lubrcating air compressor, Diesel portable screw air compressor, Electric

portable screw air compressor, Air dryer, Adsorption machine and the matching spare parts. CZPT adheres to the business philosophy of

cooperation and mutual benefit to provide a one-stop service for every customer!

CZPT air compressors not only cover the domestic market but also are exported to more than 20 countries and regions such as South

Africa, Australia, Thailand, Russia, Argentina, Canada and so on. CZPT products have won a good reputation from users for their excellent

quality and style. The company has always adhered to the concept of quality first, service first and dedication to providing every customer with

excellent products and meticulous after-sales service!

CZPT warmly welcome customers to visit our factory and establish a wide range of cooperation!

Frequency Asked Question:

Q1: Are you factory or trade company?

A1: We are factory.

Q2: What the exactly address of your factory?

A2: Our Factory is Located in Xihu (West Lake) Dis. County, HangZhou City, ZheJiang Province, China.

Q3: Will you provide spare parts of your products?

A3: Yes, We provide all parts to customer, so you can do repair or maintenance without trouble.

Q4: Can you accept OEM orders?

A4: Yes, with professional design team, OEM orders are highly welcome.

Q5: How long will you take to arrange production?

A5: Immediate delivery for stock products.380V 50HZ we can delivery the goods within 3-15 days. Other voltage or other color we will delivery within 25-30 days.

Q6: Warranty terms of your machine?

A6: Two years warranty for the machine and technical support always according to your needs.

Q7: Can you provide the best price?

A7:According to your order, we will provide you the best price. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours |

|---|---|

| Warranty: | 1 Year, 2 Year |

| Lubrication Style: | Oil-free |

| Cooling System: | Air Cooling |

| Power Source: | AC Power |

| Cylinder Position: | Horizontal |

| Customization: |

Available

|

|

|---|

Basic knowledge of vacuum pump

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its main job is to create a relative vacuum within a given volume or volumes. There are many types of vacuum pumps. This article will describe how they work, their types, and their applications.

How it works

A vacuum pump is a mechanical device that removes gas from a system by applying it to a higher pressure than the surrounding atmosphere. The working principle of the vacuum pump is based on the principle of gas transfer and entrapment. Vacuum pumps can be classified according to their vacuum level and the number of molecules that can be removed per cubic centimeter of space. In medium to high vacuum, viscous flow occurs when gas molecules collide with each other. Increasing the vacuum causes molecular or transitional flow.

A vacuum pump has several components that make it a versatile tool. One of the main components is the motor, which consists of a rotor and a stator. The rotor and stator contain coils that generate a magnetic field when excited. Both parts must be mounted on a base that supports the weight of the pump. There is also an oil drain that circulates oil throughout the system for lubrication and cooling purposes.

Another type of vacuum pump is the liquid ring vacuum pump. It works by positioning the impeller above or below the blades. Liquid ring pumps can also adjust the speed of the impeller. However, if you plan to use this type of pump, it is advisable to consult a specialist.

Vacuum pumps work by moving gas molecules to areas of higher or lower pressure. As the pressure decreases, the removal of the molecules becomes more difficult. Industrial vacuum systems require pumps capable of operating in the 1 to 10-6 Torr range.

Type

There are different types of vacuum pumps. They are used in many different applications, such as laboratories. The main purpose of these pumps is to remove air or gas molecules from the vacuum chamber. Different types of pumps use different techniques to achieve this. Some types of pumps use positive displacement, while others use liquid ring, molecular transfer, and entrapment techniques.

Some of these pumps are used in industrial processes, including making vacuum tubes, CRTs, electric lights, and semiconductor processing. They are also used in motor vehicles to power hydraulic components and aircraft. The gyroscope is usually controlled by these pumps. In some cases, they are also used in medical settings.

How a vacuum pump works depends on the type of gas being pumped. There are three main types: positive displacement, negative displacement, and momentum transfer. Depending on the type of lubrication, these principles can be further divided into different types of pumps. For example, dry vacuum pumps are less sensitive to gases and vapors.

Another type of vacuum pump is called a rotary vane pump. This type of pump has two main components, the rotor and the vacuum chamber. These pumps work by rotating moving parts against the pump casing. The mating surfaces of rotary pumps are designed with very small clearances to prevent fluid leakage to the low pressure side. They are suitable for vacuum applications requiring low pulsation and high continuous flow. However, they are not suitable for use with grinding media.

There are many types of vacuum pumps and it is important to choose the right one for your application. The type of pump depends on the needs and purpose of the system. The larger ones can work continuously, and the smaller ones are more suitable for intermittent use.

Apply

Vacuum pumps are used in a variety of industrial and scientific processes. For example, they are used in the production of vacuum tubes, CRTs, and electric lamps. They are also used in semiconductor processing. Vacuum pumps are also used as mechanical supports for other equipment. For example, there may be multiple vacuum pumps on the engine of a motor vehicle that powers the hydraulic components of an aircraft. In addition, they are often used in fusion research.

The most common type of vacuum pump used in the laboratory is the rotary vane pump. It works by directing airflow through a series of rotating blades in a circular housing. As the blades pass through the casing, they remove gas from the cavity and create a vacuum. Rotary pumps are usually single or double-stage and can handle pressures between 10 and 6 bar. It also has a high pumping speed.

Vacuum pumps are also used to fabricate solar cells on wafers. This involves a range of processes including doping, diffusion, dry etching, plasma-enhanced chemical vapor deposition, and bulk powder generation. These applications depend on the type of vacuum pump used in the process, and the vacuum pump chosen should be designed for the environment.

While there are several types of vacuum pumps available, their basic working principles remain the same. Each has different functions and capacities, depending on the type of vacuum. Generally divided into positive displacement pump, rotary vane pump, liquid ring pump, and molecular delivery pump.

Maintenance

The party responsible for general maintenance and repairs is the Principal Investigator (PI). Agknxs must be followed and approved by the PI and other relevant laboratory personnel. The Agknx provides guidelines for routine maintenance of vacuum pump equipment. Agknxs are not intended to replace detailed routine inspections of vacuum pump equipment, which should be performed by certified/qualified service personnel. If the device fails, the user should contact PI or RP for assistance.

First, check the vacuum pump for any loose parts. Make sure the inlet and outlet pressure gauges are open. When the proper pressure is shown, open the gate valve. Also, check the vacuum pump head and flow. Flow and head should be within the range indicated on the label. Bearing temperature should be within 35°F and maximum temperature should not exceed 80°F. The vacuum pump bushing should be replaced when it is severely worn.

If the vacuum pump has experienced several abnormal operating conditions, a performance test should be performed. Results should be compared to reference values to identify abnormalities. To avoid premature pump failure, a systematic approach to predictive maintenance is essential. This is a relatively new area in the semiconductor industry, but leading semiconductor companies and major vacuum pump suppliers have yet to develop a consistent approach.

A simplified pump-down test method is proposed to evaluate the performance of vacuum pumps. The method includes simulated aeration field tests and four pump performance indicators. Performance metrics are evaluated under gas-loaded, idle, and gas-load-dependent test conditions.

Cost

The total cost of a vacuum pump consists of two main components: the initial investment and ongoing maintenance costs. The latter is the most expensive component, as it consumes about four to five times the initial investment. Therefore, choosing a more energy-efficient model is a good way to reduce the total system cost and payback period.

The initial cost of a vacuum pump is about $786. Oil-lubricated rotary vane pumps are the cheapest, while oil-free rotary vane pumps are slightly more expensive. Non-contact pumps also cost slightly more. The cost of a vacuum pump is not high, but it is a factor that needs careful consideration.

When choosing a vacuum pump, it is important to consider the type of gas being pumped. Some pumps are only suitable for pumping air, while others are designed to pump helium. Oil-free air has a different pumping rate profile than air. Therefore, you need to consider the characteristics of the medium to ensure that the pump meets your requirements. The cost of a vacuum pump can be much higher than the purchase price, as the daily running and maintenance costs can be much higher.

Lubricated vacuum pumps tend to be more durable and less expensive, but they may require more maintenance. Maintenance costs will depend on the type of gas that needs to be pumped. Lighter gases need to be pumped slowly, while heavier gases need to be pumped faster. The maintenance level of a vacuum pump also depends on how often it needs to be lubricated.

Diaphragm vacuum pumps require regular maintenance and oil changes. The oil in the diaphragm pump should be changed every 3000 hours of use. The pump is also resistant to chemicals and corrosion. Therefore, it can be used in acidic and viscous products.

editor by Dream 2024-05-13

China OEM Buna Rubber Ball Fit for Pump Spare Parts Diaphragm Vacuum Pump vacuum pump oil near me

Product Description

Product Description

| Product Name | NBR/EPDM/BUNA Balls | Material | NBR/EPDM/BUNA |

| Brand | N/C | Color | BLACK |

| Feature | Resistance to Acid and Alkali/Excellent Insulating Properties | Application | Use for petrochemical industry, machinery, electronics, ball valves, aerospace,electrical appliances and other fields |

| Pressure | Low Pressure | Modes of packing | PE bags+carton |

| Sample time | 10-20days | Delivery Time | 7-15days |

| Place of Product | ZheJiang Province,China | Shipment | DHL, FedEx, UPS, TNT… |

Rubber ball is widely used in petrochemical industry, machinery, electronics, ball valves, electrical appliances,aerospace and other fields.PTFE can resist most chemicals and PTFE balls can reduce the bumps when corrosive reagents boil.

Performance

1.The products is used epdm as a material ,and it has excellent chemical stability,such as electrical insulation and aging resistance,high lubricity,non-stick properties and corrosion resistance.

2.High lubrication, the lowest coefficient of friction among CHINAMFG materials. Non-adhesion is the smallest surface tension of CHINAMFG materials, and does not adhere to any substances.Corrosion resistant, inert to most chemicals and solvents, resistant to strong acids and alkalis, water and various organic solvents.

More products:

Certifications

Packaging & Shipping

Company Profile

ZheJiang Zhaohui Fluoroplastic Products Co., Ltd. is a specialized manufacturer of fluoroplastic products and engineering plastic products.

Its products include pneumatic diaphragms, pneumatic diaphragm valve diaphragms, oil-free bearings, PTFE seals, ball valve seats, and various seals.PTFE bellows, engineering plastic products, reactors and tank linings, O-rings, V-rings and other products.

The company is headquartered in Xihu (West Lake) Dis. County Industrial Park, HangZhou, ZheJiang Province, ZheJiang Zhaohui Fluoroplastic Products Co., Ltd., has a complete Scientific quality management system. ZheJiang Zhaohui Fluoroplastic Products Co., Ltd. is an enterprise recognized by the industry for its integrity, strength and product quality. Welcome friends from all walks of life to visit ZheJiang Zhaohui Fluoroplastic Products Co., Ltd. for visit, guidance and business negotiation. We sincerely make friends from all over the world with reasonable price and reliable quality.

FAQ

-Q: Are you trading company or manufacturer?

-A: We are professional manufacturer of fluoroplastic products and engineering plastic products with ISO9001,and all material are Food Grade compliant.

-Q:How can we guarantee quality?

-A:Always a pre-production sample before mass production; Always final Inspection before shipment.

-Q: I have a drawing, can you produce?

-A: First, please send your drawing to our sales representative, they will CHINAMFG all the information to our engineer and evaluate our capacity, a detail proposal will be reply with 24 hours.

-Q: I have a PTFE sample but don’t have drawing, what can i do?

-A: In this situation, firstly please send us some photos of your sample, we will evaluate. If our factory can produce, then secondly we will ask sample from you, the Draftsman will make drawings according your sample,and make sure the sampel is new.

-Q: The price on website will be the same as the price I will order?

-A:The price we indicate is only a approximate price. The final price will be re-calculated based on size, design, packing , material and quantity.

-Q: What’s you lead time?

-A: 10 days after payment. It depends on the product quantity and designs.

-Q: What’s is your payment method?

-A: TT, Trade assurance by alibaba.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Rubber Ball |

|---|---|

| Product Name: | Rubber Ball |

| Material: | Rubber |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are diaphragm vacuum pumps environmentally friendly and compliant with regulations?

Diaphragm vacuum pumps are generally considered to be environmentally friendly and compliant with regulations. Here’s a detailed explanation:

Environmental Friendliness: Diaphragm vacuum pumps offer several features that contribute to their environmental friendliness:

– No Oil Lubrication: Diaphragm pumps operate without the need for oil lubrication, which eliminates the risk of oil contamination in the vacuum system. This is particularly important in applications where oil vapor contamination could affect product quality or pose environmental hazards. The absence of oil lubrication also reduces the need for oil changes and disposal, resulting in lower environmental impact.

– Low Noise Emission: Diaphragm pumps are known for their relatively quiet operation compared to other types of vacuum pumps. The reduced noise emission makes them more environmentally friendly, particularly in settings where noise pollution needs to be minimized.

– Energy Efficiency: Diaphragm vacuum pumps can be designed to be energy-efficient, consuming less electrical power compared to other vacuum pump types. Reduced energy consumption not only contributes to cost savings but also helps reduce the overall environmental impact associated with energy usage.

– Chemical Compatibility: Diaphragm pumps are available in models constructed with chemically resistant materials. This allows them to handle corrosive gases or chemical vapors without degradation or release of harmful substances, further ensuring environmental compatibility.

Regulatory Compliance: Diaphragm vacuum pumps are designed and manufactured to meet regulatory standards and requirements. They are commonly used in various industries and applications where compliance with environmental and safety regulations is crucial. Some specific regulations that diaphragm vacuum pumps may comply with include:

– Restriction of Hazardous Substances (RoHS): Diaphragm pumps are often manufactured to comply with RoHS directives, which restrict the use of hazardous substances such as lead, mercury, cadmium, and certain flame retardants in electrical and electronic equipment.

– CE Marking: Diaphragm pumps intended for sale within the European Economic Area (EEA) are required to bear the CE marking, indicating compliance with relevant European Union (EU) directives related to health, safety, and environmental protection.

– International Electrotechnical Commission (IEC) Standards: Diaphragm vacuum pumps may adhere to specific IEC standards that ensure their safety, performance, and environmental compatibility.

It’s important to note that while diaphragm vacuum pumps are generally considered environmentally friendly and compliant with regulations, it’s essential to select pumps from reputable manufacturers and suppliers. This ensures that the pumps meet the necessary standards and certifications applicable to a specific industry or application.

In summary, diaphragm vacuum pumps are environmentally friendly due to their oil-free operation, low noise emission, energy efficiency, and chemical compatibility. They are designed and manufactured to comply with regulatory standards and requirements, such as RoHS directives, CE marking, and IEC standards. When choosing diaphragm vacuum pumps, it’s advisable to verify that they come from reliable sources and meet the necessary certifications for your specific application to ensure environmental compatibility and regulatory compliance.

How do diaphragm vacuum pumps handle condensable vapors and liquids?

Diaphragm vacuum pumps have certain mechanisms in place to handle condensable vapors and liquids encountered during operation. Here’s a detailed explanation:

When diaphragm vacuum pumps encounter condensable vapors or liquids, the following methods are typically employed to handle them:

– Condensate Traps: Diaphragm vacuum pumps often incorporate condensate traps in their design. These traps are positioned in the vacuum line and are specifically designed to capture and collect condensable vapors and liquids. The traps typically consist of a cooled surface or a series of baffles that cause the condensable substances to condense and collect in a separate reservoir, preventing them from entering the pump.

– Chemical Resistance: Diaphragm pumps are often constructed using materials that are resistant to the corrosive effects of condensable vapors and liquids. Materials such as PTFE (polytetrafluoroethylene) or other chemically resistant polymers are commonly used in the construction of diaphragm pumps to ensure compatibility with various liquids and vapors encountered in different applications.

– Separation and Filtration: In some cases, diaphragm vacuum pumps may incorporate separation and filtration mechanisms to handle condensable substances. These mechanisms can include filters or coalescing elements that help to separate the liquid or vapor from the gas stream, allowing the gas to be pumped while preventing the liquid or vapor from entering the pump.

It’s important to note that while diaphragm vacuum pumps can handle condensable vapors and liquids to a certain extent, there are limitations. If the amount of condensable substances is excessive or if the pump is not specifically designed to handle certain types of condensates, it may lead to pump performance issues or damage. In such cases, it may be necessary to implement additional vapor traps, cold traps, or other specialized equipment to effectively manage the condensable substances.

In summary, diaphragm vacuum pumps handle condensable vapors and liquids through the use of condensate traps, chemical-resistant materials, and separation/filtration mechanisms. These features help prevent the condensable substances from entering the pump and ensure reliable and efficient operation.

What are the typical applications of diaphragm vacuum pumps in laboratories and industries?

Diaphragm vacuum pumps find widespread use in laboratories and various industries due to their versatile capabilities. Here’s a detailed explanation of the typical applications of diaphragm vacuum pumps in laboratories and industries:

In Laboratories:

– Laboratory Research and Analysis: Diaphragm vacuum pumps are extensively used in laboratories for various research and analytical applications. They provide vacuum conditions necessary for techniques such as filtration, degassing, rotary evaporation, centrifugation, and vacuum ovens. Diaphragm pumps are also used in analytical instruments like gas chromatographs, mass spectrometers, and vacuum-based sample preparation systems.

– Medical and Healthcare: Diaphragm pumps are employed in medical and healthcare settings for applications such as vacuum filtration in microbiology, vacuum aspiration in clinical laboratories, vacuum sealing of sterilized containers, and vacuum drying in medical device manufacturing. They are also used in dental clinics for suction and aspiration procedures.

– Environmental Monitoring and Analysis: Diaphragm vacuum pumps play a crucial role in environmental monitoring and analysis. They are used for air sampling, gas collection, and monitoring of pollutants in ambient air or emission sources. Diaphragm pumps are utilized in environmental testing laboratories for sample preparation and analysis, such as water and soil testing.

In Industries:

– Vacuum Filtration: Diaphragm vacuum pumps are commonly used in industries for filtration processes. They create a vacuum to draw liquids through a filter medium, separating solids from the liquid. This technique is widely employed in industries such as pharmaceuticals, biotechnology, food and beverage, and chemical processing.

– Vacuum Drying and Degassing: Diaphragm pumps facilitate vacuum drying and degassing processes in industries. They help remove moisture or volatile substances from materials or products under vacuum conditions. This is crucial in industries like electronics manufacturing, automotive, aerospace, and materials science.

– Automotive and Manufacturing Processes: Diaphragm vacuum pumps find applications in automotive and manufacturing processes. They are used for vacuum-assisted molding, vacuum lifting and handling of objects, vacuum packaging, and vacuum-based testing or leak detection in components and systems.

– Semiconductor and Electronics Manufacturing: Diaphragm pumps are extensively utilized in the semiconductor and electronics industry. They provide vacuum conditions for processes such as wafer handling, thin film deposition, etching, and packaging. Diaphragm pumps are preferred due to their oil-free operation, which prevents contamination of sensitive electronic components.

These are some of the typical applications of diaphragm vacuum pumps in laboratories and industries. The versatility, oil-free operation, chemical resistance, and compact design of diaphragm pumps make them suitable for a wide range of applications, contributing to their popularity across various sectors.

editor by Dream 2024-05-13

China Custom Industrial Vacuum Pump Air Oil Water Rotary Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pump with Great quality

Product Description

Industrial Vacuum Pump Air Oil Water Rotary Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pump

industrial vacuum pumps

Rotary vane: Rotary vane pumps are comprised of a series of vanes that are mounted to a rotor that turns inside a cavity. As the vanes rotate, centrifugal force extends them from their individual slots, forming compression cells that get larger to draw air in from the intake and smaller to push air out the exhaust.

Articulated piston: An articulated piston industrial vacuum pump operates in a manner similar to that of an automobile engine. As the piston moves downward inside the cylinder, air is drawn in through the intake valve. During the piston’s upward stroke, the air is permitted to escape via an exhaust valve. Two spring-backed piston rings are used to seal the piston to the cylinder.

Screw: Rotary screw pumnps include 2 parallel rotary screws in the pump housing. The screws are synchronized to turn in opposite directions, which causes the compression action to occur. The gas is compressed in the direction of the pump’s discharge port.

Liquid ring: Liquid ring pumps also operate via positive displacement. During operation, the pump’s impeller rotates inside the pump casing. A rotating liquid ring then seals the impeller and its blades. Liquid is sucked into the compression chamber to keep the ring stable. Conveyed gas is compressed during each impeller revolution.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Oil Free |

|---|---|

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Work Function: | Mainsuction Pump |

| Working Conditions: | Dry |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety features are typically integrated into diaphragm vacuum pump systems?

Diaphragm vacuum pump systems typically incorporate various safety features to ensure safe operation and protect both the users and the equipment. Here’s a detailed explanation:

1. Overpressure Protection: Diaphragm vacuum pump systems often include overpressure protection mechanisms to prevent excessive pressure buildup. These mechanisms can be in the form of pressure relief valves or pressure sensors that automatically shut off the pump or release excess pressure if it exceeds the predefined limits. Overpressure protection safeguards the system from potential damage and reduces the risk of accidents or equipment failure.

2. Thermal Protection: Thermal protection features are designed to prevent the pump from overheating. Diaphragm pumps can generate heat during operation, especially in continuous or intensive use. Thermal protection mechanisms, such as thermal switches or temperature sensors, monitor the pump’s temperature and automatically shut it down or activate cooling systems if the temperature exceeds safe limits. This helps prevent damage to the pump and reduces the risk of fire or other safety hazards.

3. Leak Detection: Diaphragm vacuum pump systems may incorporate leak detection mechanisms to alert users in case of any air or gas leakage. These mechanisms can include pressure sensors or flow sensors that monitor the system’s integrity. If a leak is detected, visual or audible alarms may be triggered, indicating the need for immediate attention and repair to maintain the system’s efficiency and prevent the release of potentially harmful substances into the environment.

4. Electrical Safety: Diaphragm pump systems have electrical safety features to protect against electrical hazards. This includes measures such as ground fault circuit interrupters (GFCI) or residual current devices (RCD) that detect and interrupt electrical faults, preventing electric shocks or short circuits. Proper grounding and insulation of electrical components are also important safety considerations in diaphragm pump systems.

5. Emergency Stop: Many diaphragm pump systems are equipped with an emergency stop button or switch that allows users to quickly shut down the pump in case of an emergency or hazardous situation. The emergency stop feature provides a convenient and immediate means to halt pump operation, ensuring the safety of the users and preventing further risks or damages.

6. System Monitoring and Alarms: Advanced diaphragm pump systems may incorporate monitoring features that continuously assess the system’s performance and provide real-time feedback. This can include monitoring parameters such as vacuum levels, temperature, pressure, or flow rates. Alarms or visual indicators are often integrated to alert users in case of deviations from normal operating conditions, enabling prompt corrective actions and preventing potential safety issues.

It’s important to note that the specific safety features integrated into diaphragm vacuum pump systems may vary depending on the manufacturer, model, and intended application. Users should carefully review the product documentation and follow the manufacturer’s instructions regarding safety precautions, installation requirements, and maintenance procedures to ensure safe and proper use of the equipment.

In summary, diaphragm vacuum pump systems typically incorporate safety features such as overpressure protection, thermal protection, leak detection, electrical safety measures, emergency stop functionalities, and system monitoring with alarms. These safety features aim to protect users, prevent equipment damage, and ensure the safe and reliable operation of the diaphragm pump system.

Are there variations in diaphragm vacuum pump designs, and how do they affect performance?

Yes, there are variations in diaphragm vacuum pump designs, and these variations can affect the performance of the pumps. Here’s a detailed explanation:

Diaphragm vacuum pumps are available in different designs and configurations to meet specific application requirements. The design variations can impact several aspects of the pump’s performance, including: